![]()

Member Credit: Voboy

Now before getting started my initial impressions on the key fob:

I got mine from RemoteHub on ebay.

You’ll want to buy the one that is the conversion case and transponder chip only (TRANSPONDER CHIP THAT CAME FROM EBAY WILL NOT BE USED!!!).

Initial impressions were that the case was relatively cheap, felt a little weaker than the OEM key fob that came with the car. Switchblade assembly was good and strong though. I was a little disappointed because I felt like I paid $40 bucks for a weak piece of plastic and a key. I would have been satisfied if this product had cost $20-$25, or at least come with the key fob components for $40. So for potential buyers I would recommend try to find a cheaper retailer, or wait it out for paypal/ebay coupons (10$ off shipping would be the best one to use!) But RemoteHub does offer 10% off around the end of the month even though that only saves you a buck or two 😛

After everything has been said and done and the project was completed, I’m happy that I did it, its a simple and stupid mod but I always liked the Euro flip style on the VW’s so I’m glad there was such a thing out there for Nissan’s.

—————————–

Well lets get started:

Estimated cost: $35-$50

Difficulty: 3/10

Tools/Stuff needed:

Your current key, & key fob

Euro flip style conversion case with key

New key fob (optional)

Small screwdriver

Small flathead

Small pliers

Exacto blade or knife

Some other cutting utensil (optional but would make getting the transponder chip out easier)

Blow dryer (optional)

Super glue

Masking tape

—————————-

There are a couple ways you can approach this. You can either use your key fob or buy a new one and reprogram it.

Either way you’re gonna be destroying one. That said I used my OEM key fob because I didn’t need an extra one.

(Your Key will not have a transponder chip in it at the end of this so there’s no point in getting another key fob IMO)

The hardest part of this project is probably destroying your OEM key and trying to get the transponder chip out.

Second hardest was reassembling everything. (May have been easier if I secured the circuit board for the key fob, so that the components didn’t fall out while trying to reassemble, but I didn’t think about that while do it)

—————————–

INSTUCTIONS:

1. Slice open your OEM key, along the side where you can see the seal. Use the blade to break the seal and just keep cutting along until the casing will open enough to wear you can pry it open with the small flathead.

2. Now you’ll see how the transponder chip has been installed. You’ll want to use the exacto blade or some other cutting tool (I’d think an air tools sander/saw would work well here) to cut up a few of the walls that the chip is placed in.

3. Now heat up casing with the blow drier to see if the chip will budge if it does slow pry it out, be careful not to damage it. If this doesn’t work continue to work on other walls until you can pry the chip free. (try your best to keep the key casing in chunks rather than small small pieces so you can put it back together without the chip. You’re done with the hardest part!

4. Put back together the OEM key with the transponder chip removed, I taped it up with masking tape so that its holdable, keep the chip in a safe spot for now and go get the key copied. If you do it like this no one gives you a hard time about it having a chip in it or not because well.. it doesn’t! I was skeptical about doing it at a regular hardware store instead of the dealership because my local Sears Hardware employee didn’t have a clue what “tape” to use for the copy. But I told them it was a Nissan and they got it done. When everything was said and done the imprints on the copied were a little different but the valleys were exact. It worked in the car for me and only cost me $1.60 so good deal!

5. Now with the switchblade key cut, you’ll work on the key fob components

a) Open up your current key fob (stick in a flat head or key on the bottom end next to the panic button and turn)

b) Take a look a good look at how everything is placed. Open up the flip style case with the small screwdriver. The key and spring and button will come apart but just leave that to the side.

c) You’ll need to slice the with the exacto blade panic button off and slice off the clear keypad panic button also. (This is right under the red panic button) – Why do this? because the switchblade key only has 3 button openings, the panic cannot be used because it is located at the bottom, the 4th button. It simply will not fit in the case even if you didn’t want to cut it and tried to pack it in.

d) Transfer the remaining buttons, keypad and board into the switchblade case.

e) Now on the other side of the OEM key fob there’s the battery and battery holder/plate. Transfer this to the other side of the switchblade case.

f) Super glue the transponder chip in the designated area of the switchblade case as seen above. Just add a drop or two, place it in and let it dry. Now I’m not sure if the direction the chip is important or not but I put it like it was on the OEM key, the smaller area towards the key insert. ex:

6. Reassemble the switchblade case

This might be a little difficult if you don’t know how the switchblade works.

a) Assemble the button, key, and spring. Assemble this to the side where the key fob buttons are and hold with your right hand with the buttons facing your palm so the key/spring/button don’t fall out. (The actual key should be held by your fingers along side of the case, (Closed form) As seen in picture below:

b) Grab the other board, now join the two the two boards together by placing the bottom of the spring on the base with the battery (There’s an insert for the bottom of the spring leg, fits only one way)

c) The key flips out counter clockwise so you’ll need to rotate counter clockwise just once after you’ve seated the spring. Attach both sides together hold it firmly together with one hand.

d) Start screwing the case back together with the other hand. Make sure the all buttons work and the key flips out.

7. *Optional step* The switchblade case should have come with the a Nissan sticker to go on the back. Peel the sticky and place it on the back to cover up the hole for screws.

You’re done!!!

—————————–

I hope this clears up some things for people who were confused by the original thread. Sorry I didn’t take pictures along the way! If you’re still confused and really set on this project go buy it and once you have the key fob and switchblade case open you’ll understand very quickly and see how simple this mod actually is. Learn from experience!

Have to give thanks to g35driver guys for originally bringing the switchblade topic up, but also to kevincat b/c he actually found a nice Nissan case and posted on here, and thanks for his pics again!

Best of luck to all!

If you’re still confused let me know your questions and I’ll try my best to edit this thread to answer them.

![]()

Member Credit: Eddy

Let’s face it, we don’t always have time to wait for car parts in the mail. Especially when you need it quick and don’t have time to be running around (i.e. Starter Went or Bad Battery). If you are in that situation, Advanced Auto parts is a great cost efficient option given the many coupon codes you can use to save money.

Please keep in mind that you do have to be a SpeedPerks members to take advantage. But it’s FREE to become member, so why not!

The best way to take advantage of these coupon codes it to order online and pick up in store. It usually shows up in the system within 15 mins although the order notifications state an hour. So order from home and by the time you get to the store, you should be able to find the item and take it to the register.

Advance Auto also has FREE shipping to your home on any order over $75, or you can have most items shipped free to one of their local stores.

ADVANCE AUTO COUPON CODES

————————————–

- TRT30 (30% Off)

- ES123 ($10 off $30, $20 off $50)

- TRT37 ($30 off $75)

- TRT41 ($40 off $100)

There are other promo codes available, but these are the only 4 you need to maximize your savings.

If you are spending the following amounts, use the corresponding codes listed below.

$00.01-$29.99 TRT30 (30% Off) ($0-$9 off)

$30.00-$33.33 ES123 ($10 Off)

$33.34-$49.99 TRT30 (30% Off) ($10-$15 off)

$50.00-$74.99 ES123 ($20 Off)

$75.00-$99.99 TRT37 ($30 Off)

$100.00-$133.33 TRT41 ($40 Off)

$133.34+ TRT30 (30% Off) ($40-$50 off)

![]()

Member Credit: FTC.gov

Auto Warranties, Routine Maintenance, and Repairs: Is Using the Dealer a Must?

If you own a car, you know how important it is to keep up with routine maintenance and repairs. But can a dealer refuse to honor the warranty that came with your new car if someone else does the routine maintenance or repairs?

The Federal Trade Commission (FTC), the nation’s consumer protection agency, says no. In fact, it’s illegal for a dealer to deny your warranty coverage simply because you had routine maintenance or repairs performed by someone else. Routine maintenance often includes oil changes, tire rotations, belt replacement, fluid checks and flushes, new brake pads, and inspections. Maintenance schedules vary by vehicle make, model and year; the best source of information about routine scheduled maintenance is your owner’s manual.

What is a warranty?

A warranty is a promise, often made by a manufacturer, to stand behind its product or to fix certain defects or malfunctions over a period of time. The warranty pays for any covered repairs or part replacements during the warranty period.

Do I have to use the dealer for repairs and maintenance to keep my warranty in effect?

No. An independent mechanic, a retail chain shop, or even you yourself can do routine maintenance and repairs on your vehicle. In fact, the Magnuson-Moss Warranty Act, which is enforced by the FTC, makes it illegal for manufacturers or dealers to claim that your warranty is void or to deny coverage under your warranty simply because someone other than the dealer did the work. That said, there may be certain situations where a repair may not be covered. For example, if you or your mechanic replaced a belt improperly and your engine is damaged as a result, your manufacturer or dealer may deny responsibility for fixing the engine under the warranty. However, according to the FTC, the manufacturer or dealer must be able to demonstrate that it was the improper belt replacement — rather than some other defect — that caused the damage to your engine. The warranty would still be in effect for other parts of your car.

Will using ‘aftermarket’ or recycled parts void my warranty?

No. An ‘aftermarket’ part is a part made by a company other than the vehicle manufacturer or the original equipment manufacturer. A ‘recycled’ part is a part that was made for and installed in a new vehicle by the manufacturer or the original equipment manufacturer, and later removed from the vehicle and made available for resale or reuse. Simply using an aftermarket or recycled part does not void your warranty. The Magnuson-Moss Warranty Act makes it illegal for companies to void your warranty or deny coverage under the warranty simply because you used an aftermarket or recycled part. Still, if it turns out that the aftermarket or recycled part was itself defective or wasn’t installed correctly, and it causes damage to another part that is covered under the warranty, the manufacturer or dealer has the right to deny coverage for that part and charge you for any repairs. The FTC says the manufacturer or dealer must show that the aftermarket or recycled part caused the need for repairs before denying warranty coverage.

Tips To Avoid Warranty Issues

Here’s how to get the most out of your vehicle’s warranty:

- Read your warranty. Often bundled with your owner’s manual, the warranty gives a general description and specific details about your coverage. If you have misplaced your owner’s manual, look for it online. Check the “Owners” section of your manufacturer’s website.

- Be aware of your warranty period. If problems arise that are covered under the warranty, get them checked out before the warranty expires.

- Service your car at regular intervals. This is a good idea in any case. But for the sake of keeping your warranty intact, follow the manufacturer’s recommended service schedule. Details are in your owner’s manual.

- Keep all service records and receipts, regardless of who performs the service. This includes oil changes, tire rotations, belt replacement, new brake pads, and inspections. Create a file to keep track of repairs; it will come in handy if you have to use your warranty. If you ever have a warranty claim and it appears that you did not maintain your vehicle, your claim could be denied.

- Complain. If you think a dealer’s service advisor denied your warranty claim unfairly, ask to speak with a supervisor. If you still aren’t satisfied, contact the manufacturer or go to another dealer. You also may wish to file a complaint with your state Attorney General, local consumer protection office, local Better Business Bureau, or the FTC.

![]()

Member Credit: omahasubaru

Materials you will need:

– canvas material from a local fabric store.

– heavy duty thread

– heavy duty velcro

– some rope/string or zip ties

Tools you will need:

– Fabric tape measure

– Scissors

– Pencil or fabric marker

– Sewing machine

Other items that may be useful:

– Spare fabric to use for your first template

– Ability to use this DIY as a guideline and interpret/adjust as needed.

– A measure twice cut once mindset

– Patience

– Skill with the sewing machine, or a friend who does

Phase One : Building a template

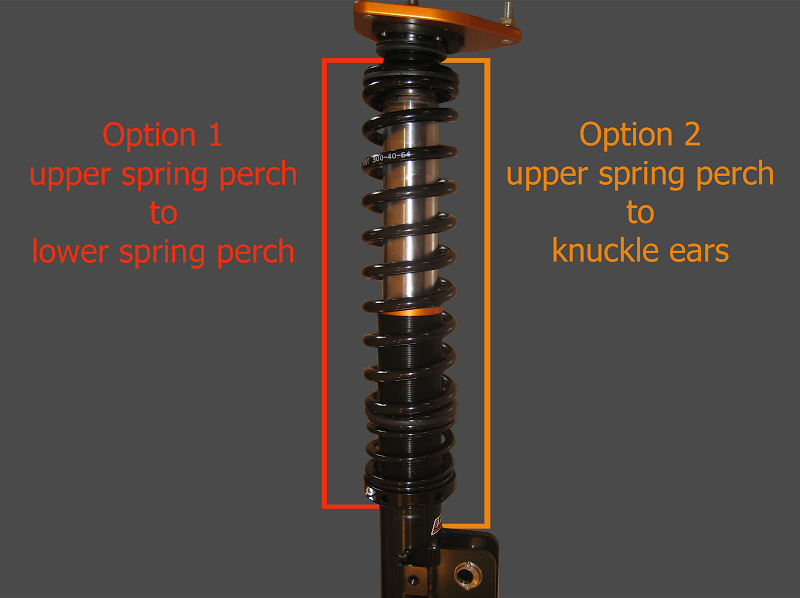

There are a few ways to do your covers. I’m only going to cover the two more popular ways.

1) Measure your springs and perches

You’ll want to use the fabric tape measure for this. Measure around the widest part you want to cover. Sometimes this is the upper or lower perch, other times it is spring. Especially if you have some of the newer Hypercoil OBD springs. Take this measurement and add around 1.25-1.5″ to it and write it down. This helps to account for overlap and velcro strip.

2) Measure your coilovers for the length you want to cover.

This is where options come in. You can either measure from above the upper perch and just to below your lower spring perch, or you can measure all the way down to the knuckle ears if you want. Neither way is wrong, but I prefer the latter, as it covers any remaining exposed un-used threads you may have. Please be aware that not all struts are the same length. You rears will likely be longer than the front, so you may have to make two patterns for best results. Write down your measurements.

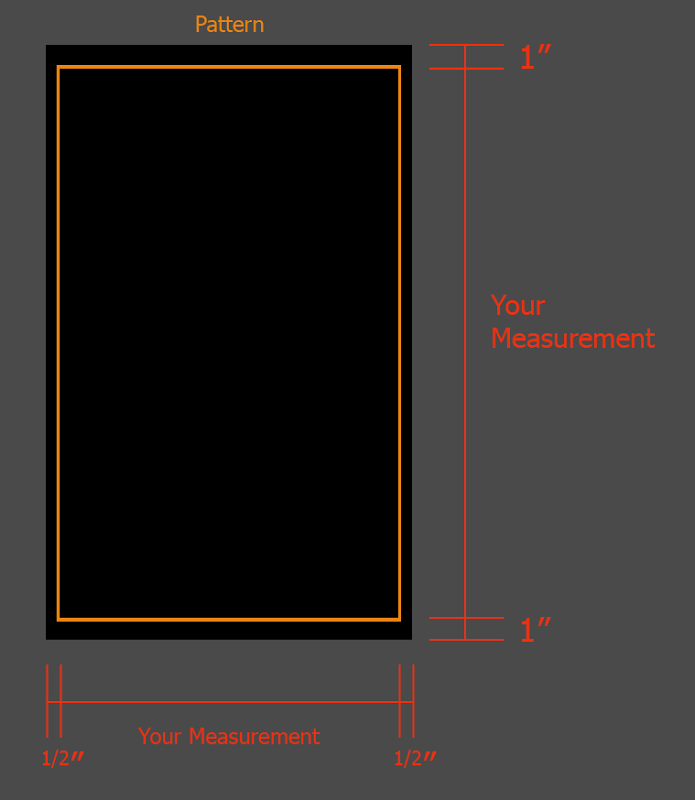

3) Build your template

Take your measurements and use the guide here to add to them. You have to add to account for folding over and stitching. This also gives you just a little more length depending on how good your measurements were. Your measurement goes on the inside of the lines in the template below.

The top/bottom has a longer fold to account for room to run your rope/string or ziptie through to snug up the ends.

4) Test fit it.

It should be over-sized at this point, but this is a great time to catch any issues you may have with your measurements before you go further.

Phase Two : Make your bags

Now we take your cut out pattern and start to put it together.

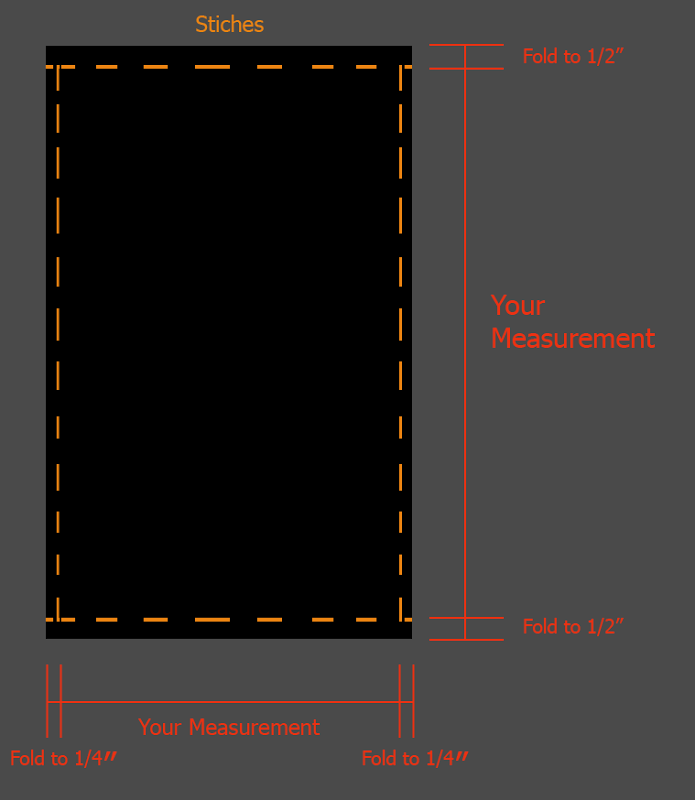

1) Fold & stitch your pattern.

Use this guide below to setup your folds and location of your stitching. You don’t want to stitch the ends closed as then you can’t run your rope or tie through to snug up the ends. Use the zig-zag stitch pattern on the sewing machine.

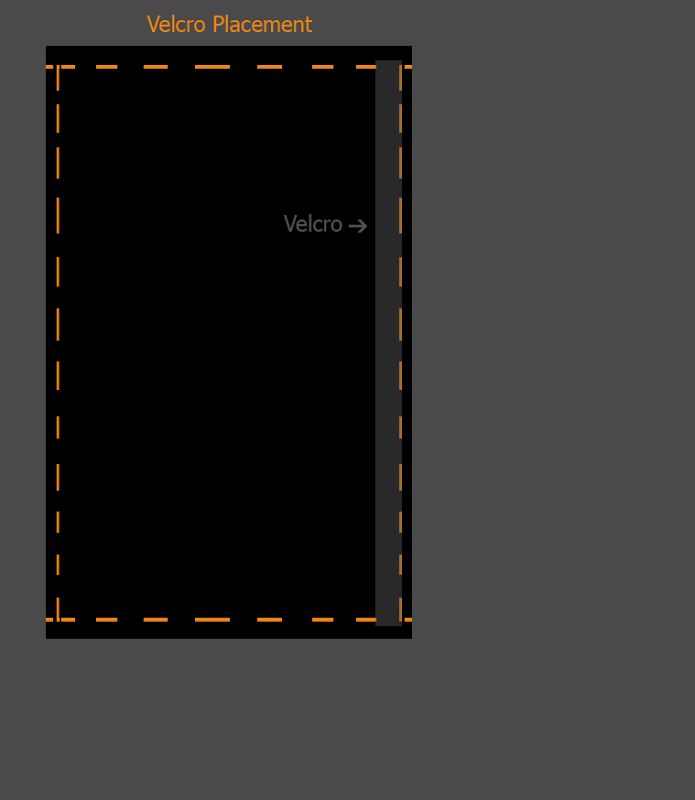

2) Place your velcro & stitch it on.

Use the guide below to determine where to locate it. You need to place one side of the velcro on one end and stitch it on. Then place the matching side of the velcro on the other side of the fabric on the opposite end. This is so when you wrap it, the velcro meets up correctly. Use the straight stitch pattern on the sewing machine.

3) Test fit it.

Now it should fit quite well and should look something like this.

4) Choose your snug method.

This is where you decide if you want to use some rope/string material to snug up the ends, or zip ties. I initially went with some nylon rope, but have since had concerns about how well it would stay tied and have elected to go with zipties. My intended use for the car and the [COLOR=blue ! important][COLOR=blue ! important]suspension[/COLOR][/COLOR] is scca rallycross events and lots of gravel road use. So I really didn’t want my bags to sag.

Phase Three : Repeat & Enjoy

Now you merely continue to make your remaining coil bags and then put them to use.

Thanks for checking out my DIY, I hope someone can find it useful.

![]()

Member Credit: TC from Zmods

Tools Required:

– Z32 front caliper rebuild kit

– 14MM Socket & ratchet

– Torque wrench

– Bench Vice

– Air Compressor

– Fine tipped awl

– Bench grinder with a wire wheel

– 2 cans of brake cleaner

– Acetone or lacquer thinner

– 2 cans of high temperature paint in the color of your choice

– High temperature clearcoat (optional, but recommended)

– Set of Speed Bleeders (optional, but recommended)

– Set of stainless steel brake lines (optional, but recommended)

– 2 quarts of brake fluid, brand of your preference

!!!WARNING!!! – This task can be a little tricky, so if you don’t think you’re up for the job, DO NOT ATTEMPT THIS!! Brakes are nothing to fool around with if you’re not completely sure of what you’re doing!! A mistake could land you in the hospital or morgue, and your car in the junkyard!! If you have little or no experience with brake work, forget you ever saw this writeup, and let a professional handle this job!!

I also recommend purchasing a set of core calipers off a parts car to do this on, as this procedure is time consuming. It will take a few days to do it right and allow the paint to cure, in which time your car will be out of commission, which is not an option if your Z is a daily driver. Its a lot easier to do this to some spare/core calipers, that way the brake lines aren’t left open very long, and you can still drive your car while working on this. This is also a perfect time to upgrade from the scrawny 26mm calipers if you have an early 1990 model NA. When you’re finished, you can resell your original calipers and recoup your money spent on the rebuilder set you bought.

With the above out of the way, now the fun begins!!

These are a set of 30mm aluminum calipers I pulled off a 1991 Twin Turbo parts car. They were high mileage, and had definitely seen better days…..until now!!

Basic Preparation for the build

Step 1:

The first thing you want to do is remove the pads and all the pad retention hardware. If you’re reusing your old pads and not replacing them with new ones, you need to mark their orientation!! This is VERY important!! They need to go back on in the same location they came off!

Step 2:

Now that the pads and their hardware is out of the way, you now want to remove the rubber dust boots and retainer rings from the caliper pistons. Use the fine tipped awl and simply pop the metal ring off. The boot may come off with it. If it doesn’t, just grab hold of it and pull, it will come off easily. You may discard these items in the trash FOR THE FRONT BRAKES ONLY, they will not be reused. The rebuild kit contains new replacements for the front brakes. You MUST SAVE the dust boots and O rings for the rear calipers!! Be VERY careful not to puncture the dust boots with the awl during removal on your rear calipers!!! The rear rebuild kits are NLA (no longer available) from Nissan!! On this note, they VERY VERY rarely ever fail, so this is nothing to worry about, you can reuse the O rings and dust boots without fear! When you remove the O rings and dust boots from the rear calipers, simply inspect them for damage. Damage you want to look for will be torn dust boots or damaged O rings (signs of leakage, cracks or chunks missing). It’s not likely you’ll find any. If for some reason you do, you’ll need to replace that caliper.

Removing the pistons

The pistons now need to be removed from the caliper. This next sequence can be a bit tricky, especially if you have a sticky piston. A stuck piston is not too common, but it can happen. The pistons should come out fairly easily with the aid of an air compressor. If the piston is seized, the caliper may need to be replaced.

Step 1a:

Place a 2X4 up the middle of the caliper, between the pistons. Then place your air hose with a small nozzle chuck attached over the line fitting on the back of the caliper. Make sure the bleeder valve is installed and tight. Get yourself into position, making sure your fingers are NOWHERE NEAR the pistons!!! When you shoot the air into the caliper, the pistons will come out with some velocity! If your fingers are in the way, it can definitely cause injury!! When in position, give it a shot of air. The pistons will start to come out and converge on the 2X4. If any one comes completely out, leaving other still seated, slide it back in just enough to reseal, and shim the opposite side of it with thin wooden shims to keep it in its cylinder, allowing the others to come out.

Step 1b:

On the rear calipers, use the same technique, just use a thinner piece of wood. I used a piece of 3/4″ plywood, it worked fine.

Step 2:

Once all the pistons are protruding from the caliper like the ones on the left in the picture above, they should pop out with little effort. If they’re still too tight to pull by hand, you may use some large pliers. If you need to use pliers, grab the outer lip that the dust seal rests in!!!! DO NOT GRAB THE PISTON SIDES!! If you scratch or score it, the piston is ruined, as this will cause leaks!!

Step 3:

Now that all the pistons are out, you want to remove the “O” rings from the cylinders. Use your awl and carefully slide it between the ring and the slot, and raise up on the O ring. BE VERY CAREFUL NOT TO DIG INTO OR SCRATCH THE O-RING SEAT!! Again, this will cause irreparable damage, resulting in a leaky caliper!! When you’re all done, this is what you should have:

Splitting the caliper halves

In this sequence, we will be splitting the two caliper halves apart.

Step 1:

Place the caliper in your bench vise, and snug it down.

Step 2:

Using a 14MM socket & ratchet, loosen all 4 of the bolts. Once all 4 are loosened, go ahead and remove them from the caliper. Make sure you have a hold of the caliper half that’s not in the vise, as when the bolts are removed, it may fall.

Step 3:

Separate the halves, paying VERY close attention to two small O rings between the halves!!! They may fall to the floor or stick to the caliper. DO NOT LOSE THESE!! The kit does NOT include replacements for them, so these need to be kept safe for reuse during reassembly!!

Chemical cleaning the calipers

Ok, this sequence is chemical washing of the caliper. This is where those cans of brake cleaner will be used. I did this outside, as it can be messy.

Step 1:

You want to douche (< heh) the caliper halves VERY thoroughly!! Make sure you get the fluid journals and the cylinders clean of all fluid and dirt, same with the exterior. I recommend wearing rubber gloves when doing this, as the brake cleaner can irritate your skin, and you WILL get some on your hands!! I have tough skin when it comes to things like this, and I’ll admit, this stuff bothered me.

Step 2:

Let them dry, it won’t take long, the cleaner evaporates fast. When done, they should look similar to this:

Wire wheel the calipers and hardware

This sequence is also another self explanatory one. You want to wire wheel all the embedded and caked on brake dust off. I strongly recommend wearing a respirator or dust mask when doing this!! Brake dust is contains asbestos. Not something you want to be inhaling!

Step 1:

Run the wire wheel over all accessible surfaces of the halves. You want to get into all the crevices, removing as much of the dust as you can. DO NOT allow the wire wheel to get into the cylinders!!! Also, do not wheel the mating surfaces where the halves join. Make sure the O ring seats are clean and free of debris, but don’t wire wheel them if you can help it!!

Step 2:

Wire wheel the pad retention hardware and the 4 bolts as well. On the bolts, make sure you wheel off any rust or corrosion on them. Make sure you get all the crud and brake dust off the bolt heads, or this may cause problems later with the paint.

BEFORE:

After:

Calipers AFTER:

Step 3:

You now want to reunite the two halves. Put the front half in the vise. Before reuniting the halves, you may want to give the halves a blast with compressed air, just to make sure you left no dust in anything.

You now want to reunite the two halves. Put the front half in the vise. Before reuniting the halves, you may want to give the halves a blast with compressed air, just to make sure you left no dust in anything.

Step 4: <– VERY IMPORTANT!! Don’t skip this step!!

Place the O rings in their seats.

Place the O rings in their seats.

Step 5:

Place the back half onto the front half, making sure the O rings don’t shift around or move. Insert the bolts, holding the halves together with your hand, not allowing them to shift around. Hand tighten the 4 bolts.

Place the back half onto the front half, making sure the O rings don’t shift around or move. Insert the bolts, holding the halves together with your hand, not allowing them to shift around. Hand tighten the 4 bolts.

Step 6:

Torque the bolts to 60 ft lbs.

Torque the bolts to 60 ft lbs.

Preparing for paint

In this sequence, you want to mask off things that you don’t want paint in.

Step 1:

Mask off all of the cylinders, including the outer lips.

Step 2:

Place a small piece of masking tape over the front and back of the bolt holes. You don’t want paint in the threads.

Step 3:

Place something in the line hole. I used an old bleeder I had. If you use a bleeder, you’ll have to first grind the tip off it to allow it to fit. Also, make sure it’s free of any oil or brake fluid.

Step 4:

You now want to take a rag and wet it good with acetone or lacquer thinner. Wipe down the whole caliper with the soaked rag. This will remove any residual contaminants you may have gotten on the caliper from handling it after the chemical cleaning and the wire wheel cleaning. After wiping it down thoroughly, do not touch it with your bare hands again!! This is the final paint prep step before you actually spray them. If you get oil from your skin on them, the paint may not stick in those places.

Step 5:

Rig hangers to hold the calipers for painting. Do not set them on flat surfaces, you won’t be able to get the underside, and it will definitely show in the end!! When making your hangers, set them so you have 360 degree access around them, so you can coat them evenly.

Painting your calipers

This is it!! This sequence covers spraying the base coat on the calipers. I used Duplicolor’s high temp flat black as a base coat. This paint requires no primer, and can withstand temperatures up to 1200 degrees!

Step 1:

Follow the directions on the paint can, as that’s the best way to start. Lightly coat the calipers the first couple coats, letting it tack up for a few minutes between coats.

Step 2:

After two or three thin coats have been applied, start making the coats thicker. I typically use five or six coats of base on a caliper, this makes for a smooth yet robust coating. 2~3 thin coats, and 2~3 thicker coats. After your last coat, your calipers will look something like this (Yes, that is black. The paint is wet, and the flash distorts it a little. This is normal):

Step 3:

Allow the calipers to hang and dry for 24 hours.

Blocking the raised letters

This sequence will remove the paint from the raised letters, If you want the letters the same color as the calipers, you may skip this sequence.

Step 1:

You’ll need a sheet of 100 grit sandpaper and a sanding block. I used a scrap piece of a 3/4″ plywood with a flat surface. It was the perfect width to cover the lettering, but not overlap the rest of the caliper too much. This is helpful for avoiding acidents.

Step 2:

Wrap a small piece of the sandpaper around the block, making sure its pulled snug, so the paper won’t slip.

Step 3a:

Sand the lettering side to side until all the paint and texture is gone. You’re finished when you’ve got a sharp and clean brushed look.

Step 3b:

On the rear calipers, the letters are smaller and not raised as high as the fronts. Use extreme caution not to angle the block, or you’ll end up having to touch up or re-shoot the entire caliper!!!

On the rear calipers, the letters are smaller and not raised as high as the fronts. Use extreme caution not to angle the block, or you’ll end up having to touch up or re-shoot the entire caliper!!!

Step 4:

When you’re done, hang them back up, its time to clearcoat them.

When you’re done, hang them back up, its time to clearcoat them.

Applying the clearcoat

This is done similar to the paint process. I used Duplicolor wheel clear, which is high temp.

Step 1:

Apply several thin coats, allowing it to tack up between coats.

Step 2:

Apply several thicker coats, again, allowing it to tack between coats. If when applying the thicker coats, using the Duplicolor wheel clear, you may notice a white milky appearance in the coating. This is nothing to be alarmed about, it will clear up as the coating begins to cure.

Step 3:

Allow them to dry overnight before handing them. I recommend letting them sit a couple days before reinstalling, to insure it’s thoroughly dried.

Step 4:

After they’re dried, remove all the tape, old bleeder valve, and whatever you had covering the brake line opening.

Reassembly

This one is also very cut and dry. Simply reassemble everything the opposite of how you took it apart, which is outlined earlier in the writeup.

Step 1:

Clean the pistons thoroughly, removing fluid, dirt, and gunk. Just use a rag and give them a good wipe down.

Step 2a – Front caliper O ring reinstall:

The new O rings will have grease on them. Do not wipe this off! Slide the O ring into its seat, making sure that its in there uniform. They will twist up easily, so make sure it doesn’t do that. You’ll know it if it does, you’ll never get the piston back in!

Step 2b – Rear caliper O ring reinstall:

Since these are the old ones being reused, wipe them down to clean any dirt and fluid off of them. In your rebuild kit for the front calipers, you’ll notice a packet of brake grease. Use a little of this on the O rings to slick them up, and then reinstall them the same way outlined in step 2a.

Step 3:

Now it’s time to reinstall the pistons. Use a little of the pink brake grease and lube the side of the piston. Start the piston into the cylinder, and slowly push it in. DO NOT PUSH THE PISTON ALL THE WAY IN!!!!!!!!!!! You need to leave them sticking out a little to reinstall the dust boot. If they’re all the way back, its a pain to get the boot on!!

Step 4a – Reinstalling the dust boot:

Now put the dust boots on. On the rear calipers, you might want to clean them up with some brake cleaner first, to get the gunk off them. Place it over the piston, allowing the boot to seat itself in the groove on the piston. NOW, you can push the piston all the way back in!

Step 4b – Reinstalling the dust boot:

Once the piston is all the way back, massage the outer edge of the boot until you feel it slide over the lip on the cylinder and seat. Then take the retainer rings and put those back on. Simply pull the ring open at its seam, place it into the groove on the dust boot, and let go. it will snap right into place. Verify it is seated by looking at it all the way around.

Step 5:

Install your new speed bleeders if you elected for those, and tighten them down.

That’s it!!! You’re now ready to reinstall them on the car, and bleed them down! I hope you found this article useful!

![]()