Last Updated: 12/25/2017 @ 05:52 pm

Member Credit: marktab

Hi All — thanks for the other posts on maxima.org on EGR tube cleaning. I spent several hours cleaning mine, and decided to take comprehensive pictures. Enjoy!

Why are you posting so many pictures and information since this topic is often on maxima.org?

The EGR Tube cleaning took me hours to finish. Also, this cleaning job does not appear in my generic Nissan service manual, nor is it in the official Nissan service manual. People who repair cars a lot or who are advanced will NOT need this much detail (and there are many advanced or professional-level people on this forum). I consider this project as an intermediate-level service task, and the directions can help you or help someone you might pay to do it for you.

Do you recommend removing from the top or the bottom?

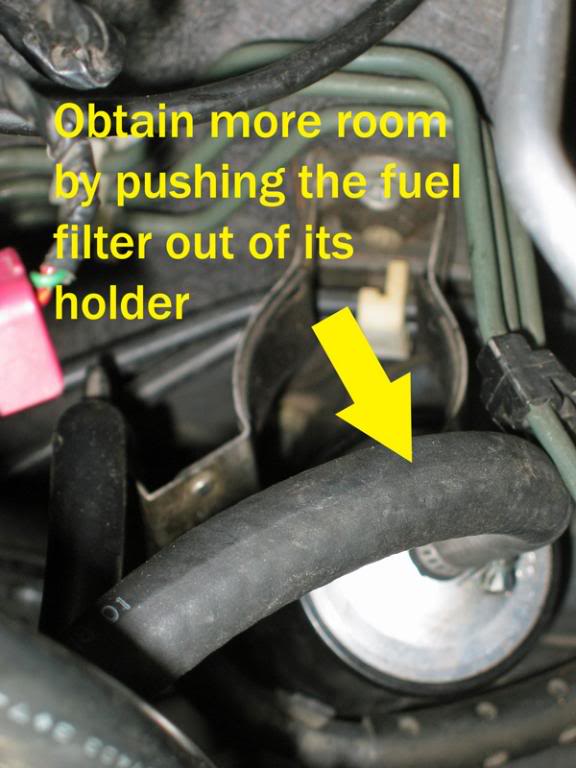

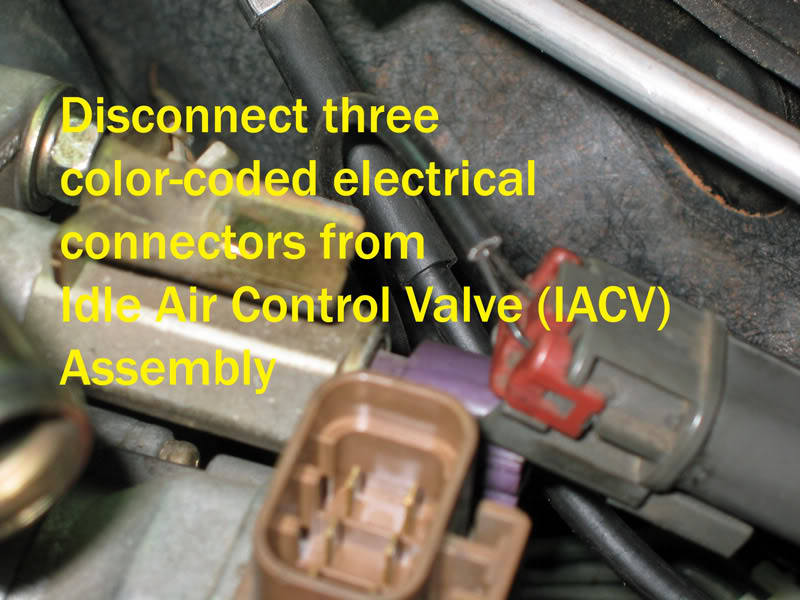

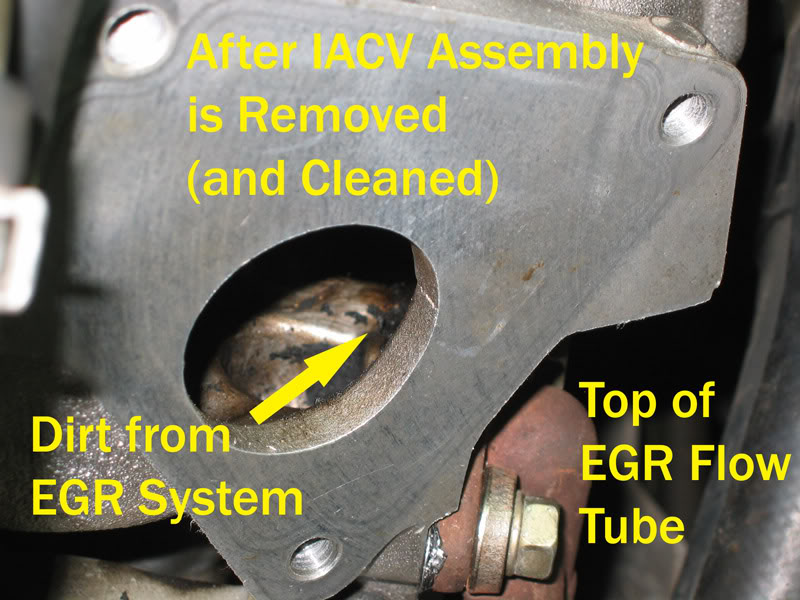

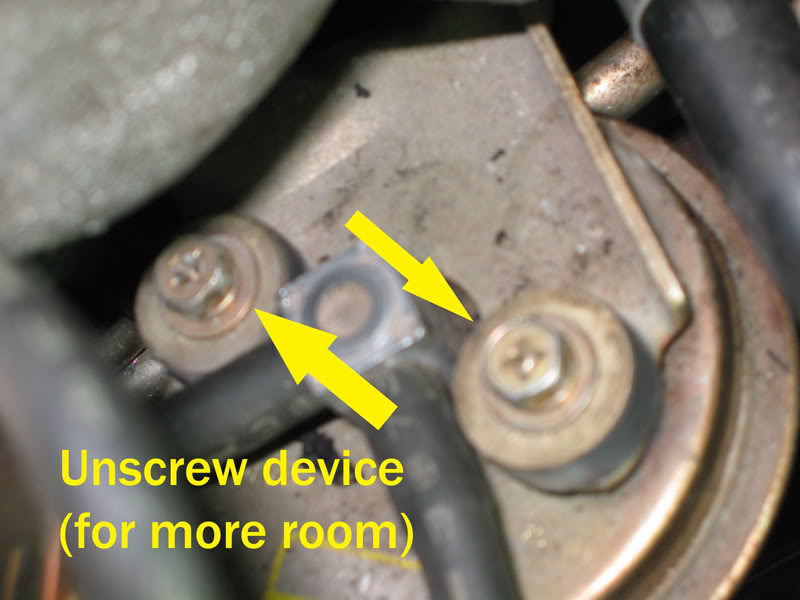

Some have had success removing the tube from the bottom (under the car). However, I believe a better solution is to remove the IACV assembly so that you can clean it. Also, the hole where the IACV assembly goes provides a way to scrape and clean the area where the EGR Tube empties into the main air flow chamber. I did NOT remove the intake manifold.

Do I need to purchase replacement gaskets?

I did not, and I made sure that I was not soaking my original gaskets with the cleaning solvent. If you do destroy yours, you could probably cut your own new ones from gasket material designed for exhaust pipes.

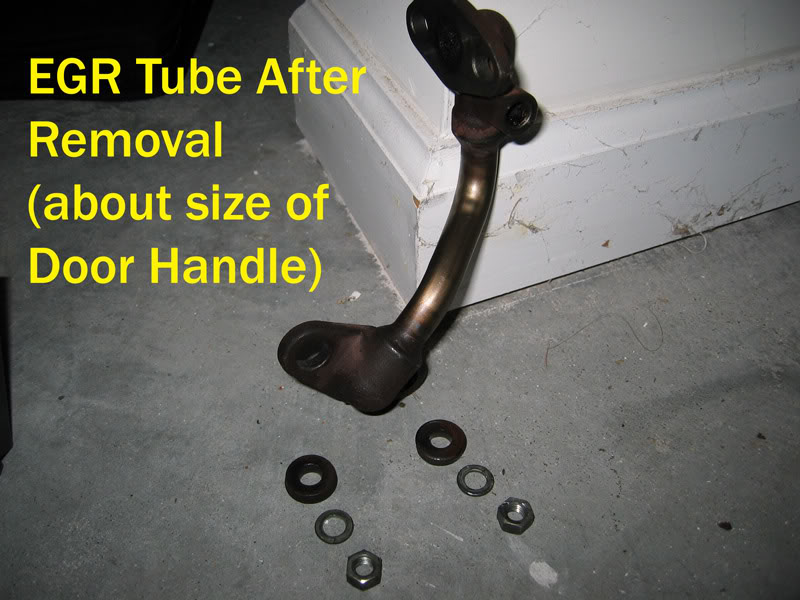

Did you replace your EGR flow tube?

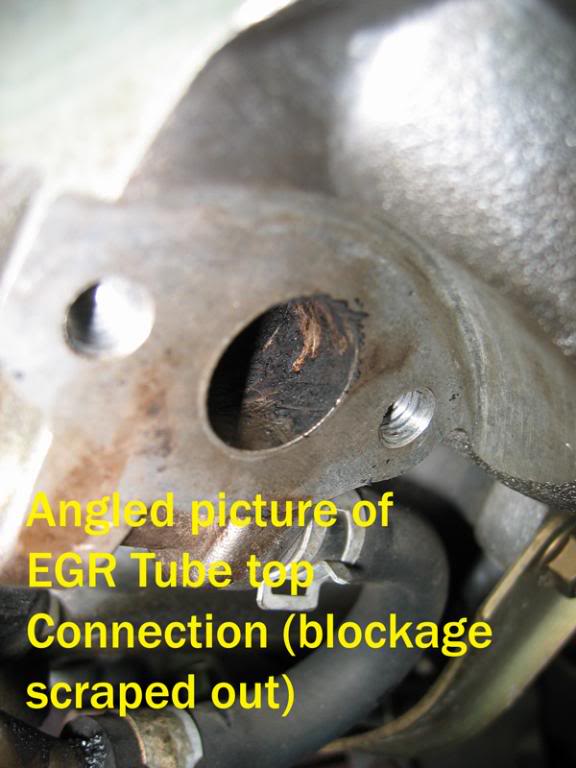

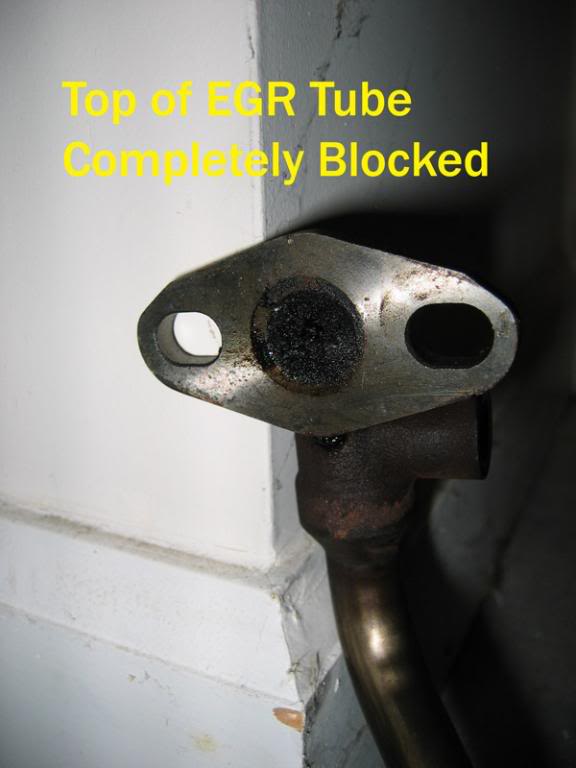

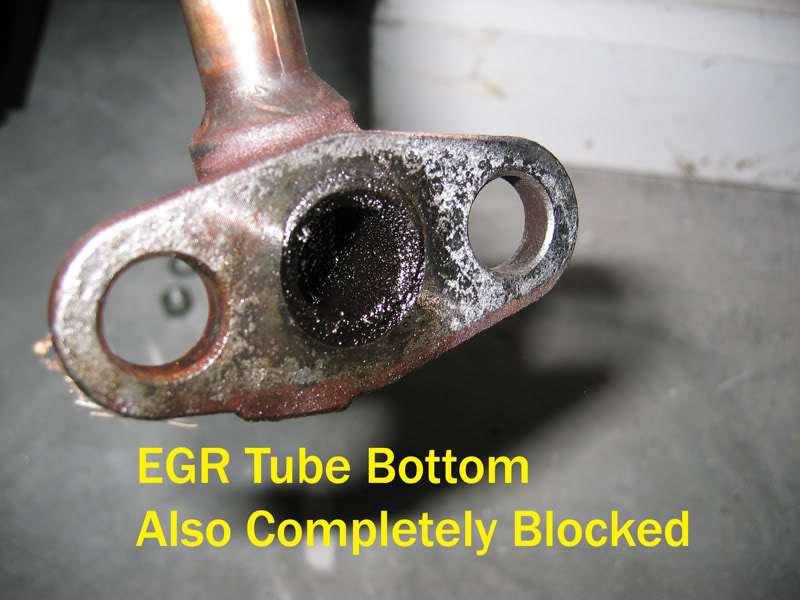

Someone mentioned that they bought a replacement tube. I think it’s sufficient to clean the tube you have unless you have some reason to get a new one (say if it rusted or cracked). Even if you buy a replacement tube, you will still need to clean the sensor off, and also the ports where the EGR tube connects to the car. I found more carbon at the top end, and I believe there was more there because of the sharp airflow angle. The IACV assembly also can be cleaned, and the IACV assembly port allows for cleaning the main airflow chamber.

How quickly can the job be completed?

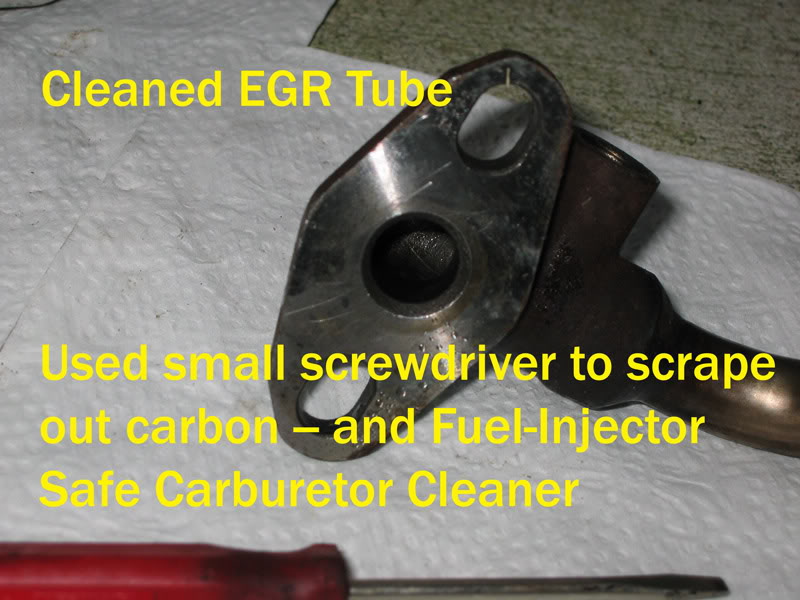

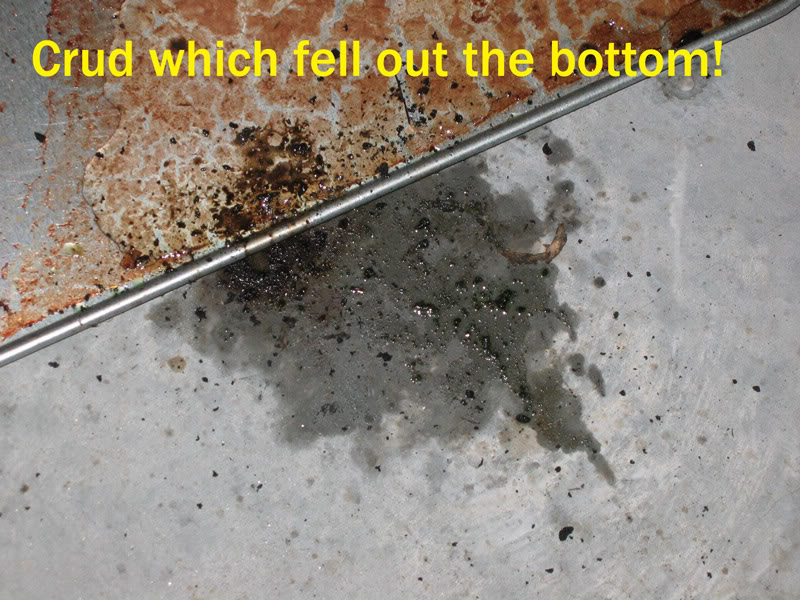

We can compare how long it takes to remove the EGR tube from the vehicle. Some say they can remove it in minutes, and I believe experienced people can do it that quickly. However, the entire time is affected by how much cleaning the tube needs, and how much time you need to clean the connection port areas and the IACV assembly. In cleaning blockage, you need to at least scrape enough out to allow airflow again, and at best, you can clean these areas back to the original bare metal surface. If someone claims to do this whole job quickly, I would wonder how much time and care they put into the cleaning. Poor cleaning will shorten the time until the next required cleaning.

How often should the EGR flow tube be cleaned?

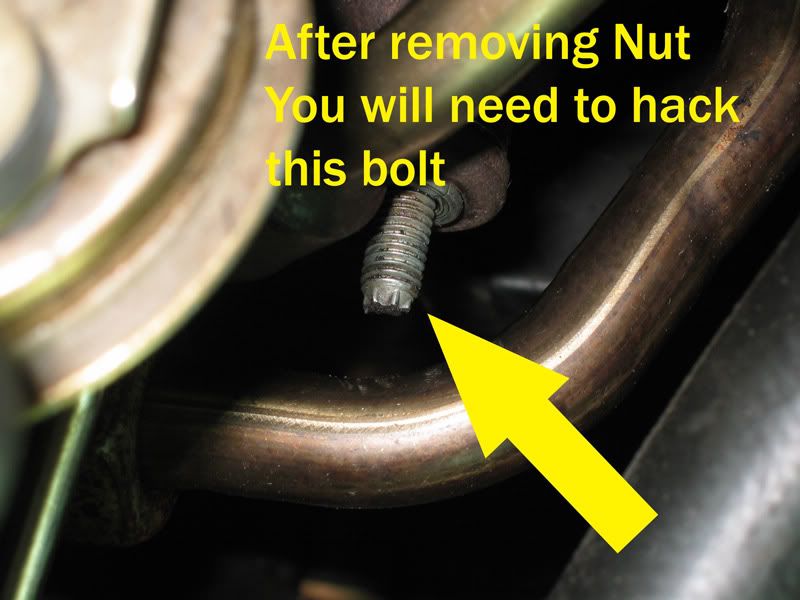

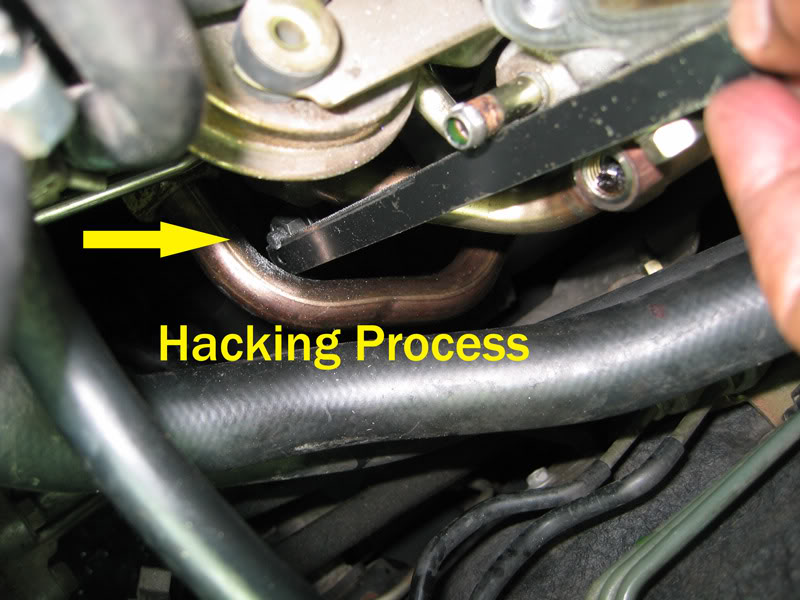

My tube was cleaned for the first time at 111K miles. It was already blocked and throwing the P0400 (same as P400) code (which is one code which will turn on the yellow engine light on the dashboard). I believe the answer varies on your oil choice, driving habits, and typical use (meaning city or highway driving). I believe that 100K is too long to wait. Now that my bottom connection nut has been hacked, cleaning it in the future will take less time.

Did the problem prevent passing emissions?

I have passed Georgia emissions every year since I got the car in 2000 (with 22K miles). This year (in January 2009), I had to replace the faulty gas cap. I do not know if this issue has been preventing people from passing emissions.

Do you recommend blowing the EGR carbon through the engine with seafoam or other solvents?

I believe that solution is NOT a good idea for this application. It is better to carefully scrape and remove the carbon deposits with fuel-injector safe carburetor cleaner. You can also spray this cleaner into the port where the IACV assembly goes. I would NOT expose my Maxima to excess oxygen or fuel, and expect it to run well, so I would NOT expect that putting extra carbon into the engine is a good idea. The carbon left by the EGR is not just black deposits on the metal wall, but thick tough carbon that I needed to carefully scrape out (mostly with a small screwdriver head).

What is the difference between cleaning the EGR flow tube and leaving it alone?

In my case, I simultaneously received the P0325 and P0400 codes together. The P0325 (or P325) code means change the knock sensor, and I was able to do that with directions from the maxima.org forum (and a replacement part from Ebay at about US$28, bought mine from the Ebay seller “abcmarts”). Changing the knock sensor alone improved my acceleration, and also improved engine starting (the engine used to require more cranking). Changing the EGR Tube has just about removed all pinging, and also improved acceleration (more). I track MPG, and have NOT seen a difference. Also, if you do NOT clean the tube, your engine will probably run (if that is your goal), but cleaning it helps restore toward the original engine performance (and probably extend engine life, even though no one could probably prove that point in all cases).

Do you believe blocking the EGR system is a good idea for Maxima fourth generation?

I do not, because of all the systems which connect into the EGR valve. You can study these connections in the official Nissan service manual (check eBay if you want to buy one). If you happen to be an automotive engineer and could prove to me comparable or superior performance using some workaround, I would like to hear about it.

Do you believe the EGR tube could be redesigned?

I believe the tube could be redesigned to allow for smoother air flow. As it is, the sensor comes into the tube at a right angle to the airflow (the sensor looks like a thermistor, a device to measure heat, and therefore a proxy for air flow). My EGR tube was most blocked at the top connection side, where the tube bends at about 90 degrees, and then goes into the main airflow chamber (and that part has a sharp bend too). None of us needs advanced automotive training to know that these sharp corners do not help airflow, and certainly not airflow filled with carbon particles. I believe a better air flow tube (and wider diameter) would be better. I have a theory that a better-designed tube would need to be cleaned less. The spacing, however, is tight, but maybe someone with good welding skills might want to fabricate and test a replacement.

So, has the light stayed off?

Yes, the light has stayed off for the last 500 miles. My story started with two engine codes, and in my case, I replaced the knock sensor first. The P0400 (same as P400) came back after less than 30 miles, and after a few weeks, I had a weekend where I decided to take on the EGR tube cleaning project.

Hopefully, this information will help you tackle the job

![]()

Comments are closed.