Last Updated: 01/31/2017 @ 02:32 am

Member Credit: shift_ice

The following how-to swaps out the factory struts and springs for Tokico Illumina struts (Part # BB3188 Front, BU2943 Rear) and Progress springs, but is generic enough to describe installation of a variety of springs/struts on the 5th gen Nissan Maxima. The install is time consuming, but can be performed at home when equipped with the proper tools in 4-6 hours.

While not required, I recommend asking a buddy to help. It will really cut down on the install time – particularly when compressing the springs.

Tools:

- Socket wrench

- Universal joint for sockets

- 19mm deep well socket

- 17mm deep well socket14mm deep well socket

- Torque Wrench

- Socket extension

- Breaker bar

- Spring compressor – Available for loan from most auto stores with deposit. I used Autozone.

- Jack stands & jack or hydraulic lift

- Lug wrench

- Utility knife or box cutters (optional – to cut bump stops if preferred)

- Pliers – preferably needle nose

- Dust boot (stock dust boot can be reused if not damaged)

- Spring isolator (stock spring isolator can be reused if not damaged. Most new springs come with isolators)

- 3M Rubber seal (I actually just used crazy glue, which works fine)

- Impact wrench (optional, but highly recommended to speed the compression of the springs and wheel removal)

- Front Wheels

1. Raise both sides of the front of the vehicle using jack and jack stands or hydraulic lift. NOTE: Struts can’t be removed with only one side raised.

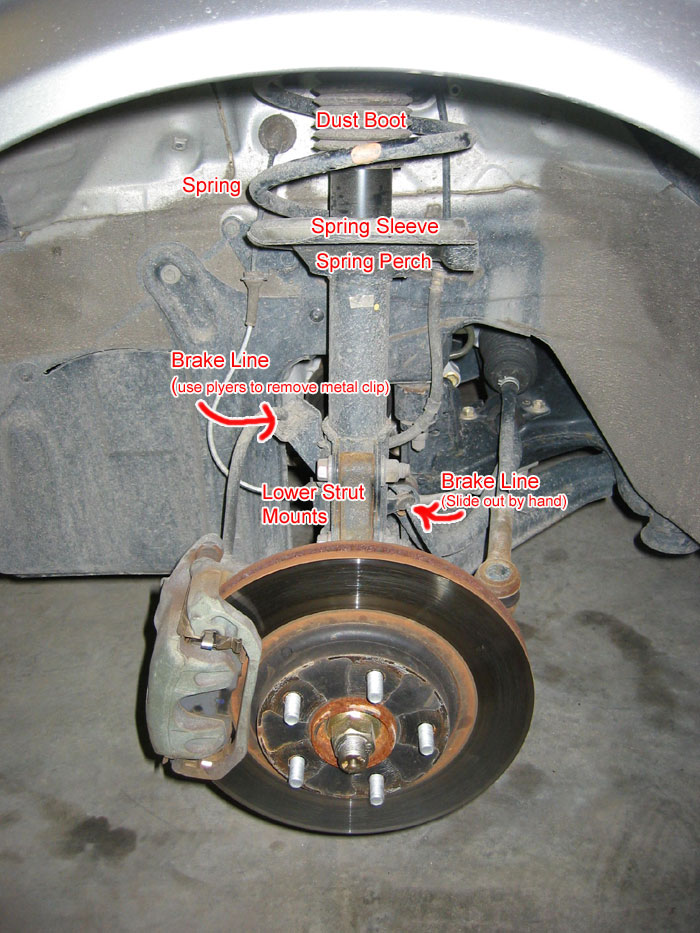

2. Remove wheel with lug wrench. Once the wheel is removed, you’ll see the strut assembly:

Note – The part labeled “Spring Sleeve” is also known as the spring isolator

3. Remove the three bolts around the center bolt. Loosen BUT DO NOT REMOVE center nut at top of strut.

4. Remove the brake line attachments on the struts. Slide the retainer clip on the left out with pliars The other break line attachment can be slid out by hand.

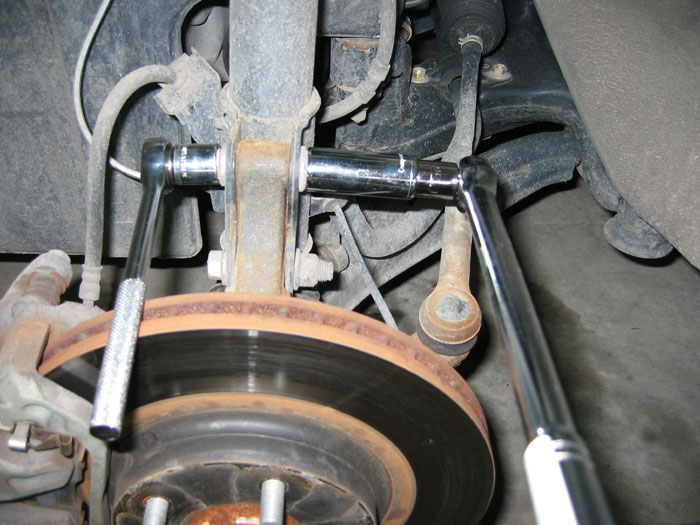

5. Use 17mm & 19mm socket wrenches to remove the two large bolts mounting the strut to the trailing arm. This requires two sockets or wrenches since the bolt on the opposite side will just spin otherwise. The strut will fall when these bolts are removed so be sure to catch it.

NOTE: There is a CV boot underneath the strut where the strut will naturally hit when it’s removed. Be sure to catch the strut when the bolts are removed to avoid damage to the CV boot below. If you really want to be safe, you can wrap your CV boot in a towel to protect it – just don’t forget to remove it when you’re done!

6. With the strut now off of the car, compress the stock spring. Make sure to compress both sides evenly – Don’t tighten down one side and then move to the other. WARNING: Compressed springs can kill. Always point the top of the strut away from you and other people and make sure spring compressor is securely fastened. Take turns slowly tightening each side until the spring is compressed enough to take the pressure off the top hat.

A few tips:

A wrench may be necessary if clearance for the socket is an issue. Or, if you have a second wrench or socket, tightening the compressor on the other side and it should loosen up the socket that’s stuck.

Try to position the compressor as close to the bottom of the spring as possible with the bolts on the compressor facing down toward the perch to avoid clearance issues with the nut on the compressor.

Don’t flip the compressors around where the bolts point toward the bottom of the spring perch – then you’ll have problems positioning the top hat properly since the long bolts on the compressor will get in the way. (Yes, the picture at the right shows the spring compressor oriented the wrong way, but do as I say, not as I do!)

Be sure to skip a coil when installing the spring compressor. Otherwise you’ll have difficulties getting the spring compressed enough. (again, not depicted in the image at the right, but I learned.)

Compressing and uncompressing the springs is a slow process. To speed things up I recommend using an impact wrench or high power drill with a socket bit and socket, u-joint and extension so the spring compressor can be tightened quickly.

7. When spring is compressed, carefully remove top hat bolt. The top hat bolt is circled in red in image at right, but the spring compressor isn’t installed in this shot.

NOTE: The spring must be compressed sufficiently with a spring compressor before you remove the top hat bolt. There may still be some pressure on the spring, causing the top hat to pop off. Be sure to point the top hat away from you!

Comparison of OEM front spring and Progress front Spring (on right):

8. OPTIONAL: Trim bump stop with razor blade or box cutters. The bump stop is connected to the dust boot and is circled in orange at the right. Tokico recommends trimming no more than 1/3 – 1/2 the length of the bump stop.

UPDATE: It appears the two rings below the orange circle are considered to be part of the bump stop as well. If anyone can confirm this, please let me know. Nonetheless, I trimmed the part circled in orange off. When I first installed my struts and springs I didn’t trim the bump stops at all and I had problems with the front bottoming out on larger bumps. Since I trimmed, this very rarely occurs. Also, most people running more mild drops (Eibachs, H&R, etc.) don’t trim their bump stops and have no issues. Most spring manufacturers provide detailed instructions on how to trim the bump stops if necessary.

9. Compress new spring with spring compressor and install on strut. Make sure the spring isolator (sleeve – gray in the picture) is installed on the spring and resting on the perch. Though not shown in this shot, the isolator should be positioned to hang off the end of the spring about 1/4″. This will avoid rubbing noises of the spring contacting the perch. Apply 3M rubber seal to attach the isolator to the spring and assure the isolator doesn’t slide around on the spring post install. Also, make sure the end of the spring is resting on the lowest part of the perch as shown at right.

10. Reinstall the top hat. Make sure the “OUT” label on top hat faces out toward the wheel well. It should be on the same side of the strut as the mounting bolts (which are being pointed to in the picture)..

11. Reinstall strut by following the removal steps in reverse order. Use the following torque specs in newton meters (N-m):

– strut to steering knuckle bolts 140-159 N-m

– strut upper mount nuts 39-54 N-m

– piston rod nut (nut that holds down top hat) 59-88 N-m <-NOTE: This is for a factory strut. Follow the torque specs for whatever aftermarket strut you’re installing otherwise.

Job half done:

REAR WHEELS

1. NOTE: The first step was formerly to remove the trunk liner, but this isn’t actually necessary. You merely need to pull away the liner over the rear struts by removing the attachments near the seat pass through.

Use a flathead screwdriver to remove the pop tabs by sliding the flathead into the slit on the side and twisting.

2. Prepare socket wrench with extension, universal joint, and 14mm deep well socket. A longer extension can be substituted for a deep well socket here if preferred. This combo makes attacking the rear strut bolts really easy.

3. Trunk stripped (Totally optional). I removed mine just so you can clearly see the rear strut towers, which are all you really need access to.

4.

Remove the two outer bolts with the socket setup mentioned above. The nut in the rear is hidden by the metal shield and represented by the orange circle. Attack the nut from above through the higher hole in the shield. The lower strut mount will continue to support the strut after these are removed.

IMPORTANT NOTE: When removing these nuts, make sure not to drop them as they’ll be very difficult to retrieve behind the black metal shield. I’d recommend using your fingers for those last few turns to assure you don’t drop the nuts. A telescopic magnetic tool would also come in handy if you happen to have one.

5. Remove the lower strut mount bolt with 17mm socket and breaker bar. Soaking with PB Blaster or WD-40 in advance may help loosen it up. The bolt is circled in orange. The strut will fall when this bolt is removed so be sure to catch it.

6. Loosen top hat nut with a 14mm deep well socket a little but DO NOT REMOVE YET. This must be loosened before the spring is compressed or the strut shaft will just spin when you attempt to loosen the top hat nut. The top hat nut isn’t visible in the shot at the right, but the red arrow is pointing to it.

7. Compress factory spring with spring compressor. WARNING: Compressed springs can kill. Always point the top of the strut away from you and other people and make sure spring compressor is securely fastened. Once the spring is compressed enough to relieve the pressure on the top hat, carefully remove the top hat bolt.

8.

Disassemble strut carefully and take note of parts and order. OPTIONAL: Trim bump stop with razor blade or box cutters. The rear bump stop is connected to the dust boot. Tokico recommends trimming no more than 1/3 – 1/2 the length of the bump stop. I trimmed a little less than 1/2 of the rear bump stops. Some spring manufacturers specify the amount the bump stop should be trimmed.

Bump stop and dust boot unit:

Before trimming:

After trimming:

9. Compress new spring.

10. Install spring on perch. Make sure the spring isolator (sleeve – gray in the picture) is installed on the spring and resting on the perch. Though not shown in this shot, the isolator should be positioned to hang off the end of the spring about 1/4″. This will avoid rubbing noises of the spring contacting the perch. Apply 3M rubber seal to attach the isolator to the spring and assure the isolator doesn’t slide around on the spring post install. Also make sure the end of the spring is resting on the lowest part of the perch as shown in the picture at the right from step #9 for the front strut. The principle is the same. Re-assemble strut and tighten top hat bolt to 59-88 nm <-NOTE: This is for a factory strut. Follow the torque specs for whatever aftermarket strut you’re installing otherwise.

11. Re-install strut assembly on car. You may have to recompress the spring and twist the top hat so the bolts line up properly on reinstallation. Use the following torque specs in newton meters (N-m):

– strut to steering knuckle bolts 140-159 N-m

– strut upper mount nuts 39-54 N-m

The finished product:

12. If you have any noises, give this checklist a look.

13. Get a four wheel alignment.

Below are shots of the drop on Progress Springs and Tokico Illuminas:

Distance from ground to center of fender.

Before:

After:

![]()

Comments are closed.