Member Credit: rpsuprdave

WARNING: It is not recommended that you attempt this procedure without basic mechanical skills and knowledge of automobiles. Always take safety precautions seriously when working around an automobile. A simple mistake may cause you physical harm and/or death. Improper installation may cause mechanical damage to the vehicle.

Materials needed:

o Remanufactured Valve Body

o Permatex Ultra Black RTV Silicone Gasket Maker

o 4 Qts Recommended Transmission Fluid

o WD-40

o Torque Wrench

o Ratchet

o Extensions

o Metric Socket Set

o Phillips Screwdriver

o Pocket Size Flat Head Screwdriver

o Regular Flat Head Screwdriver

o Needle Nose Pliers

o 10mm Hex Bit

o T-40 Torx Bit

o Digital Camera and/or Notepad

Always make sure you have a clean work environment with plenty of room to move around. A confined space is not recommended for this job.

We take no responsibility for damages done to yourself, others, or your vehicle.

INSTALL AT YOUR OWN RISK

For Top Access (Bottom and Side Access Also Required):

Remove the negative terminal from battery first, and then remove the positive terminal, both with 10mm socket.

Remove the battery clamp and battery.

Remove the fuse block on the left side of the battery plate.

Remove plastic battery tray to expose battery plate.

Remove 12mm bolts (5). Unclip wire harness from plate bracket. Use WD-40, if needed. Remove battery plate.

You will find a bracket underneath that supports the battery plate. Remove 12mm bolts (2) and bracket. You’ll need to unclip another wire harness. The valve body cover is just under this bracket and is painted black.

It is a good idea to hang the fuse block on the driver’s side of the car out of the way.

For Bottom and Side Access (Top Access Also Required):

Place the car on jack stands and remove the driver’s side front wheel.

Remove theleft wheel splash guard by carefully pry the center of each clip and remove the entire clip. DO NOT PULL THE CENTER COMPLETELY OUT OF CLIPS.

You will be able to see the bottom of the valve body cover

Remove the engine splash guard (connected to bottom of front bumper and suspension cross member) by removing the clips on the rear of guard. Carefully pry the center of each clip and remove the entire clip. DO NOT PULL THE CENTER COMPLETELY OUT OF CLIPS.

Remove the 10mm screws supporting the front of the engine splash guard and lower guard.

You should see the very bottom of the valve body cover and ATF cooler.

Remove Valve Body Cover:

Apply WD-40 to T-40 bolts (9) securing the valve body cover.

Drain transmission fluid using a 10mm hex driver into a large drain pan.

Expect 3.5 to 4 quarts of fluid to drain. Keep pan handy for valve body cover removal.

Remove T-40 bolts (9) from valve body cover. THE BOLT NEXT TO ATF COOLER IS DIFFICULT TO ACCESS!

Place drain pan underneath valve body cover. Carefully pry around edges of cover until the seal is broken. Expect fluid to escape from behind valve body cover. Remove cover, exposing the valve body assembly.

Remove Valve Body:

Important: It is a good idea to write down or photograph the connector positions and colors. In this example you will see that the rebuilt valve body has different colored connectors.

Begin by disconnecting the 5 lower solenoids using a small flathead screwdriver to push in the tab near the base of each while lightly pulling the connector out.

Remove the 10mm bolt and sensor retainer.

This is the retainer. After removing the bolt, it will slide off the sensor. DO NOT LOSE THIS RETAINER.

Carefully pull the sensor straight out of the valve body. An o-ring will be attached. DO NOT DAMAGE THIS SENSOR OR O-RING.

Disconnect the top three solenoids using a small flathead screwdriver. A pocket clip type flathead is too long to remove the middle of the three solenoids. In this case, the handle was cut to reduce the overall length.

The top solenoids are difficult to remove. DO NOT BREAK TABS ON CONNECTORS. Begin by inserting the screwdriver into the connector as shown with light force. Pivot the handle of the screwdriver outward while allowing the tip to dig in and pull the connector out. GO SLOW AND BE CAREFUL. This solenoid was removed from the valve body to demonstrate connector removal.

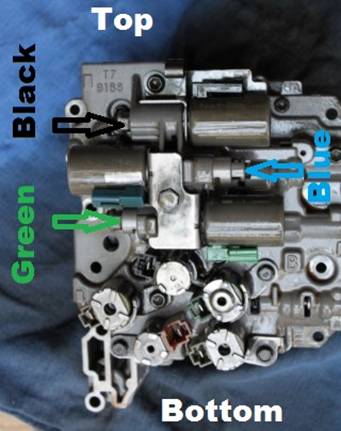

Here are the top three solenoid connector locations.

Carefully move the wire harness out of the way to prepare for valve body removal. Remove the remaining 10mm bolts in numerical order. Note that bolt 1 was removed with the sensor retainer. When removing bolt 7 be sure to catch the cover and gasket. They will be reused during installation. You will need to support the valve body while removing bolts 8 and 9.

Carefully pull the valve body away from the transmission and out through the top side of engine compartment. Pay careful attention to the manual valve, and control arm located at the very top of the valve body.

You have successfully removed your defective valve body.

Clean Valve Body Cover, Bolts and Transmission:

Now would be a good time to clean the valve body cover, bolts and mating surface on the transmission. Make sure all gasket material is removed and both surfaces are oil free and dry.

While cleaning the transmission surface, make sure that both o-rings are still inside transmission. DO NOT LOSE THESE O-RINGS. If they fall out, use a small amount of petroleum jelly to adhere them back inside transmission.

Preparing Replacement Valve Body:

Based on the car’s programming, your valve body may have a spring under the one of its valves. It is important to check for this spring’s existence and transfer to the new valve body, if required. If your valve body does not have a spring, check the new valve body for the presence of a spring and remove if required. MAKE SURE YOUR NEW VALVE BODY’S CONFIGURATION MATCHES THE OLD VALVE BODY. BE CAREFUL NOT TO DAMAGE COVER GASKET.

If valve pops up when cover and gasket are removed, a spring is present. IF VALVE APPEARS TO HAVE NO SPRING, MAKE SURE IT IS NOT STUCK.

Your replacement valve body will be shipped with the three upper solenoid/valve assemblies removed to prevent damage. They need to be installed into the replacement valve body.

Begin by removing the 10mm and 8mm bolts and brackets. The 8mm bolt secures a two piece bracket. The brackets keep the three solenoid/valve assemblies shown above in place.

Carefully insert the three solenoid/valve assemblies in the positions shown below. DO NOT INSTALL IN WRONG POSITION. EACH ASSEMBLY IS DIFFERENT. Install valve assembly brackets along with 10mm and 8mm bolts. DO NOT OVER-TIGHTEN. Your replacement valve body is ready to install.

Install Replacement Valve Body:

Take time to identify the valve body bolts. There are three types: 2 Short, 3 Long, and 4 Medium. All are 10mm.

Begin by inserting the top two bolts, labeled 1 and 2 in the picture below to hold the valve body in place. Carefully insert valve body into transmission, making sure it is lined up properly and seating onto o-rings. Pay careful attention to the manual valve, and control arm located at the very top of the valve body. The control arm must be reinserted into lever on transmission. The lever has been drawn to demonstrate proper positioning.

Hand-tighten bolts labeled 1 and 2 enough to secure valve body to transmission, and then install bolts 3 through 9 in numerical order. Be sure to reinstall cover and gasket under bolts 3 and 9. Before installing bolt 9, carefully insert sensor between bolt 7 and 9. Slide sensor bracket around sensor to hold in place, then install bolt. Lightly snug each bolt in numerical order with a ratchet, and then torque each bolt to 87 inch pounds, again in numerical order. PAY ATTTENTION TO BOLT LENGTHS AND POSITIONS.

Carefully reinstall all connectors to replacement valve body. DO NOT RELY ON CONNECTOR COLORS TO MATCH SOLENOID COLORS. Refer to your own documentation made while disassembling for connection. Start with the top three solenoids.

Next, reconnect the bottom five solenoids. Make sure the wires follow their natural shape and do not get crossed.

Take a few minutes to make sure that all wires are routed and connected properly. Your replacement valve body is now installed.

Install Valve Body Cover:

Make sure all mating surfaces and inside of valve body cover are clean, dry, and oil-free. Apply a small bead of RTV Silicon Gasket Maker to the mating surface of the valve body cover, making sure you surround each bolt hole.

Immediately install valve body cover and hand tighten T-40 bolts (9). Follow RTV Gasket Maker’s instructions for best results. Torque T-40 bolts (9) to 10 foot pounds, in the order shown below. DO NOT OVERTIGHT T-40 BOLTS. Bolt 3 is difficult to install with a conventional ratchet and extension.

Wait at least one hour to allow time for RTV gasket maker to cure, and then add 3.5 quarts of transmission fluid designed for your car. THIS IS ONLY A STARTING POINT.

Check Fluid Level:

Reinstall battery plate bracket, battery plate, battery tray, fuse block, battery, and battery clamp. Make sure that all wire clips and harnesses are returned to their original positions as you work.

Reinstall the left wheel splash guard.

Reinstall the left wheel and lower car.

Connect the positive terminal to battery.

Connect the negative terminal to battery.

Warm up the engine.

Check for any transmission fluid leaks.

Before driving, the fluid level can be checked using the “COLD” range on the A/T fluid level gauge.

The car should be level, and parking brake set.

Move the transmission selector lever through each gear position, leaving the selector lever in the “P” park position.

Check the fluid level with the engine idling.

Remove the A/T fluid level gauge and wipe it clean with a lint-free paper.

Re-insert the A/T fluid level gauge into the charging pipe as far as it will go.

Remove the A/T fluid level gauge and note the reading. If the reading is at or below the low side of the range, add the necessary specified A/T fluid through the A/T fluid charging pipe.

DO NOT OVERFILL THE TRANSMISSION.

Retrain Your Computer:

Your car’s computer has adapted to your old, defective valve body, and must learn how to correctly shift again.

If no leaks were detected, reinstall the engine splash guard (connected to bottom of front bumper and suspension cross member).

Restart your car. Slowly move the shift lever through each position beginning with P all the way to D, and then back to P. Pause for a second or two in each position. Repeat this cycle several times.

Drive slowly to a spot where starting and stopping is safe. Make sure you have room for car to advance through all gears automatically and then come to a gentle stop.

While completely stopped, move shift lever to “D” position for automatic shifting. DO NOT USE THE TIPTRONIC (L/H) SHIFTER.

Gently accelerate until 5th gear is reached. You will need to listen and count as the transmission automatically changes gears.

When 5th is reached, stop accelerating and gently apply the brake until the car has downshiffted back to 1st gear and come to a complete stop.

DO NOT BE ALARMED IF THE CAR SHIFTS ERRATICALLY DURING THIS PROCESS.

Repeat this process five times. Shifting should be smoother with each pass.

Repeat this process five more times, this time more aggressively.

Your computer has been retrained.

Park vehicle and re-check the fluid level using the “HOT” range on the A/T fluid level gauge.

DO NOT OVERFILL THE TRANSMISSION.

Carefully pack your old valve body for shipment back to rebuilder. DO NOT SHIP WITH TOP THREE SOLENOID ASSEMBLIES INSTALLED. Pack them separately in the box with ample padding. Damage to old valve body will forfeit your core refund.

Congratulations! You have just installed a Maxima Valve Body.

RPSuperDave

![]()

Comments are closed.