Member Credit: shift_ice

Pictures simply don’t do this lighting justice. Umnitza has a great product here that mimics the angel eye look found on select BMW’s, and in my opinion, clearly surpasses it. The DDE’s are ultra bright, very white, and an excellent compliment to the factory Maxima HIDs.

Umnitza provides a great how-to on CD-ROM when you purchase the DDE’s, but this how-to is helpful as a preview & supplement to the process. I performed this install multiple times and learned a few lessons along the way, so I’ve thrown in many of my own tips.

PLEASE NOTE: If you had the Nissan HID Anti-theft kit installed, the process for removing the headlights is much more involved and NOT outlined below. If your Max has the datadots install you likely have the HID anti-theft kit as well. DataDot stickers are placed on the front windows and possibly the headlights when the kit is installed. The additional bracketing itself isn’t easily visible so these stickers are the easiest indication. If you’re not in the NY area your car likely doesn’t have this kit. Sorry, to avoid abuse, I can’t provide any information on removing the kit.

Tools:

- Oven

- Cookie sheet

- Small flathead screwdriver

-

Torx bit (on some models) – otherwise a 10mm socket

- Socket Wrench

- Old towels

- 90-second epoxy

- Channel locks

- Scissors

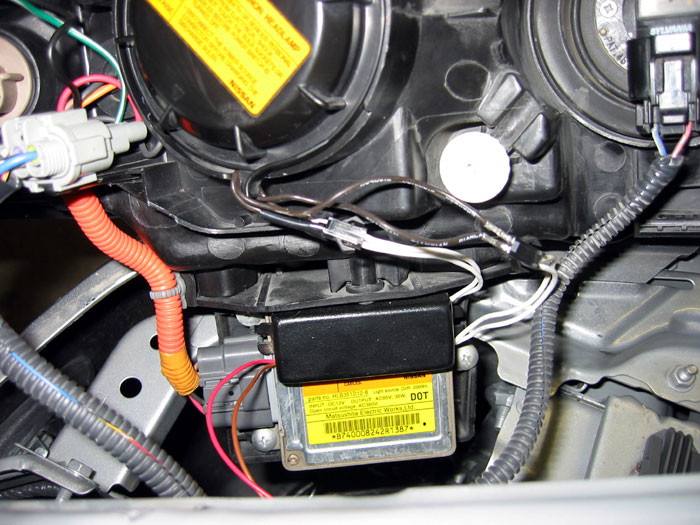

- Toothpicks or Cotton swabs

- Rubbing alcohol

- Electrical tape

For optional hardwiring (highly recommended):

- Heat-shrink tubing (optional) – Available @ Radioshack:

- Heat gun, lighter or matches

- Wire strippers

- Soldering Iron

- Solder

To wire the DDE’s as defeatable daytime running lights:

- SPDT switch (single pole dual throw)

- Around 25 feet of 22 gauge (or thicker) wire

- Heat-shrink tubing – Available @ Radioshack

- Heat gun, lighter, or matches

- 3 slide connectors

- Drill

- Drill bits

- Wire strippers

- Crimper (typically part of wire stripper)

- Hanger

- Electrical tape

INSTRUCTIONS:

1. The kit:

Test all of the rings in your kit. Take the ballast (the black rectangular box) and connect it’s wires to two of the rings. Then connect the red wire to the positive terminal on your battery and the brown wire to bare metal. The rings should light up. WARNING: When the ballast is connected to power, do NOT touch the brown and red wires together! This will blow your ballast. This warning is straight from Matt at Umnitza.2.Remove two bolts on top of the headlight (may be torx in some). Carefully pull headlight out. Pressure tabs will release. It takes surprising amount of pressure to pull the headlight out so don’t be afraid to pull. Take care not to scratch the fender with the metal mounting pin.

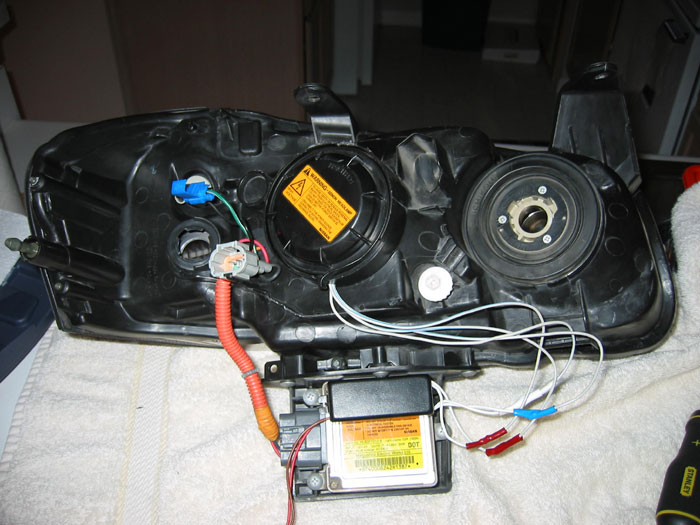

3. Remove the following from the headlight unit:

– All bulbs

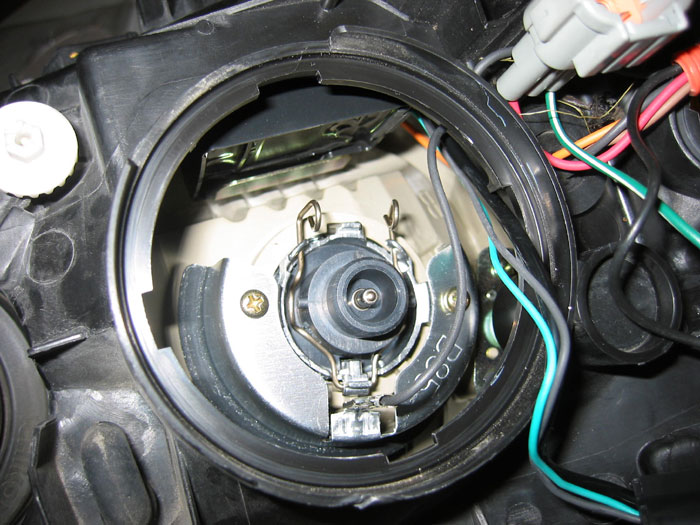

– The ballast. The ballast has the yellow and orange sticker in the picture below. It is attached with 3 screws.

– Three small screws that secure the clear housing on the front.

Everything else, including the remaining wiring, will be fine in the oven.

To remove the HID bulb, rotate the plastic cover counterclockwise. Then squeeze the 2 metal pins toward each other. Take care not to touch the bulb!

4. Wrap the headlight in an old towel and bake the headlight in oven on cookie sheet for 15-20 minutes at 200 – 250 degrees. The towel is a good idea to assure no part of the housing is directly touching the cookie sheet. Don’t let this part scare you. As long as you follow baking instructions you have nothing to worry about.

5 .Remove headlight from oven with old towels (will be very hot)

6. At this time you can also clear the blinker if you prefer

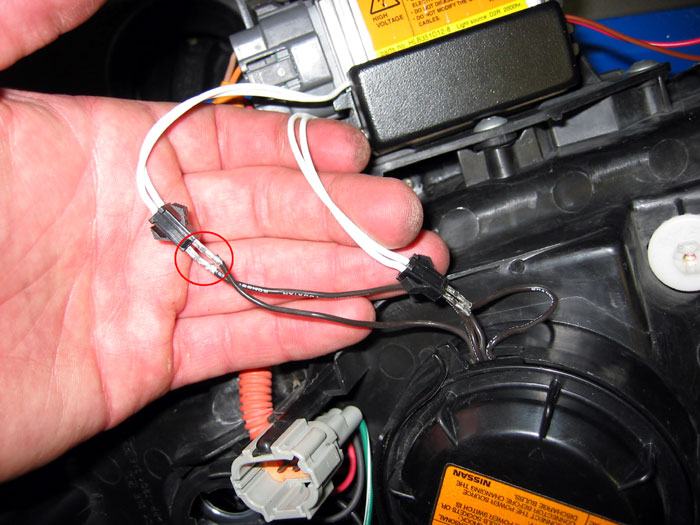

7. Use toothpicks or cotton swab to attach ring to the headlight with the small amounts of 90-second epoxy. Be careful – the rings are very fragile. Take care not to twist and bend them too much. The spots to epoxy are circled in red. After holding these points for around 2 minutes and the ring should be bonded like cement:

8. Route wires for the rings out the back of the headlight. Take care not to pull the wires

9. Reassemble headlight as best you can and return headlight to oven

10. Bake for 15-20 minutes at 200 – 250 degrees11.Remove from oven with old towels (careful – it will be very hot)12.Use channel locks to assure a tight seal. Go around the entire headlight squeezing it back together tightly while the housing is still hot. Take care not to scar the plastic – it’s easy to do when it’s hot. Using this process will assure a proper seal. No additional sealant is necessary since the factory sealant is reused.

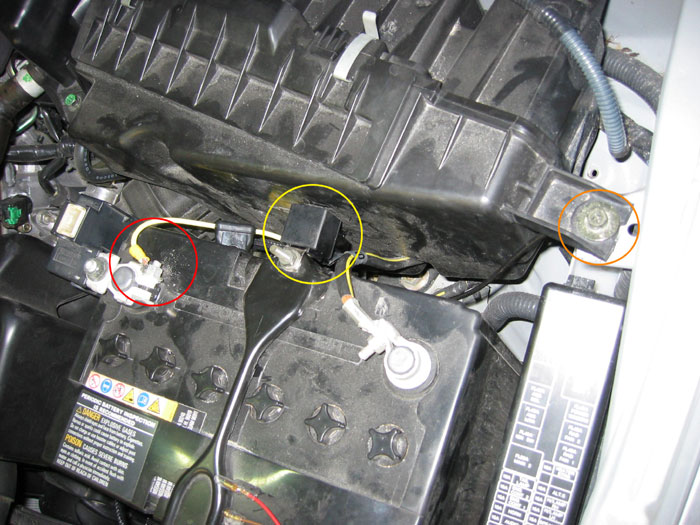

13. Connect power wire (with fuse removed) to positive terminal on battery (circled in red), ground wire securely to bare metal (circled in orange), and relay to battery tie down (circled in yellow). Be sure to scrape the paint off underneath the air box screw so the ground is attached to bare metal. Any spot where the ground can be attached to bare metal will do, so feel free to look around for alternative locations.

14. Decision time. Connect the red trigger wire to a switched power source. There are three options:

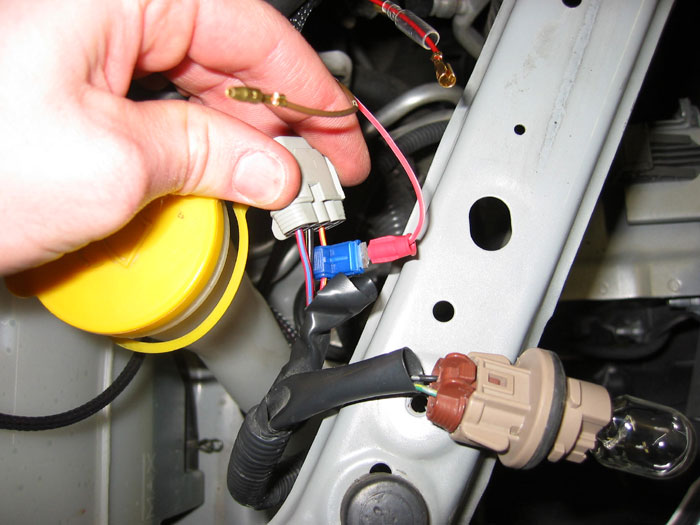

– Use the provided quick splice: Splice the red into the green wire with white stripe on the parking light or the red wire with the yellow stripe on the headlight connector. Wired this way, the DDE’s will come on when the parking lights or headlights are turned on.

– Wire the DDE’s to a switched 12V source. Wired this way, the DDE’s will be on whenever the car is on. Instructions here.

– Wire the DDE’s to a switch. This can allow you the best of both worlds: When the switch is “on” the DDE’s come on whenever the car is on. When the switch is “off”, the DDE’s come on whenever the parking lights or headlights are on. This is the setup I chose. Instructions here.

Quick Splice:

Spliced into red wire with yellow stripe on headlight clip:

15. Mount ballast for DDE’s near the headlights. One good option is the back of the headlight ballast. There aren’t many other good options since the wiring is so short. Be sure to clean area thoroughly with alcohol before attaching the ballast to assure a good bond.

16. Time to connect the rings to the ballast. This means there’s another decision to make:

– Use the provided connectors. I (and others) had problems with the connections coming loose over time. Therefore, I don’t recommend using the provided connectors. If you choose this option, make sure the small points on the connectors are oriented on the same side as the points on top of the black connector. See pic for proper orientation:

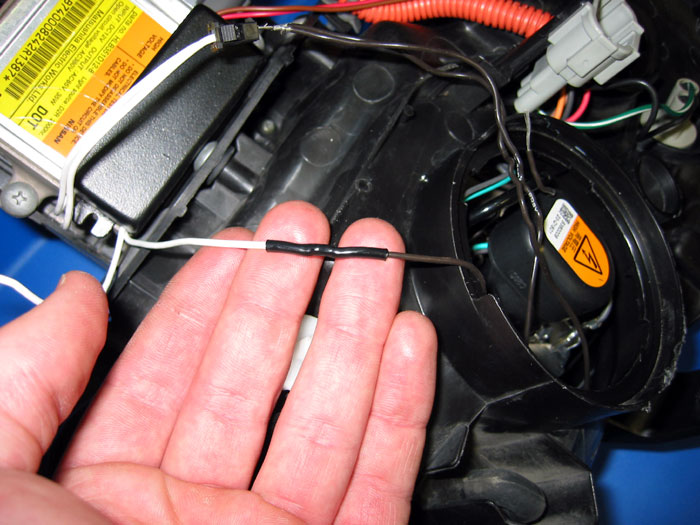

– Hard wire the rings to the ballast. Because I had problems with the connectors coming loose, I decided to hard wire the rings. This is pretty simple. Just cut the connectors off, slip heat shrink tubing over the wire, solder the wires together, slide heat shrink tubing over the connection, and shrink the tubing over the connection with a heat gun, lighter, or match. The result:

17.I also had a problem with the cap over the HID bulb rubbing through the insulation on one of my wires. To avoid this, I highly recommend either wrapping the wires in electrical tape to provide extra protection or drilling a hole under the dust cap and rerouting the wires the cap. I chose the latter. If you chose the electrical tape route, the cap will be hard to get back on with the electrical tape wrapped around the wires, but it can be done. Make sure the wires aren’t tugged on as the cap is tightened – try to hold them in the same place as you twist the cap.

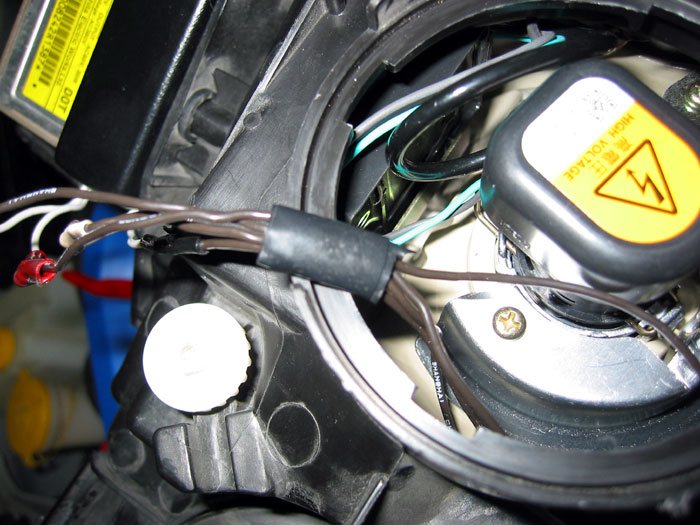

The wire that was damaged by the cap rubbing through the insulation:

The added protection with the electrical tape:

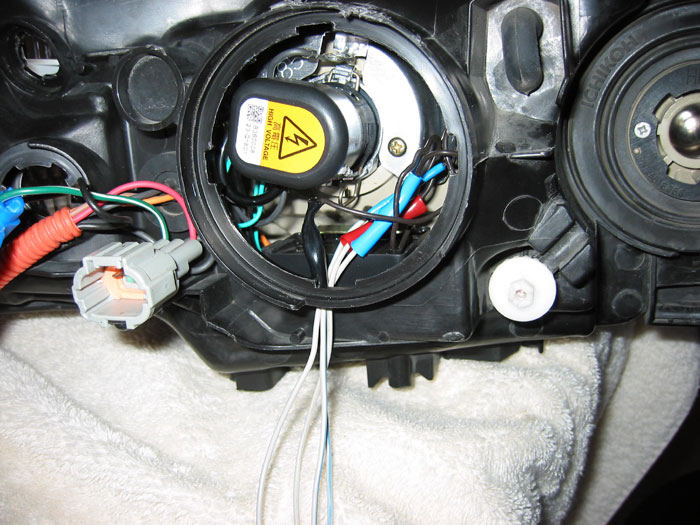

The alternative method I highly recommend is rerouting the wires by drilling a hole under the dust cap:

18. Reinstall headlight. Make sure to repress the headlight firmly to assure all pressure tabs are connected.

19.Use the black ties (included) to secure the wiring as you route the wires through the engine compartment.

20.Insert fuse and leave the parking lights out overnight to allow the hot air in the lights to escape.

21.Enjoy.

![]()

Comments are closed.