Member Credit: 6spd_Hayes

Disclaimer: If you attempt any of what you see from my post, you do so at your own risk. The following is a summary of my experience.

The Car: 2002 Maxima SE

Transmission: 6 speed, HLSD, RS6F51A

Mileage: 174,000 mi. (approx.)

Situation: November 1st, 2014. I jumped in the Maxima, running late to a funeral in Tennessee. Pushed clutch to floor and started it. I could not get gear shifter out of third gear no matter how hard I tried. Something was obviously broken in the transmission.

After a lot of online research, I purchased a 29,066 mile 6 speed, HLSD transmission from a 2006 Nissan Sentra Spec-V (p/n RS6F51H) from http://car-part.com/. Kindly gentlemen cargo shipped it from a junkyard in Arkansas to my door step in North Alabama for $XXX (will update when I remember it). The following were the only differences in the two transmissions: (1) bellhousings were different, (2) final drive ratio were different (3.812 vs 4.133), (3) Maxima – 1st & 2nd gear dual synchro, SpecV – 1st gear dual synchro, 2nd gear triple synchro.

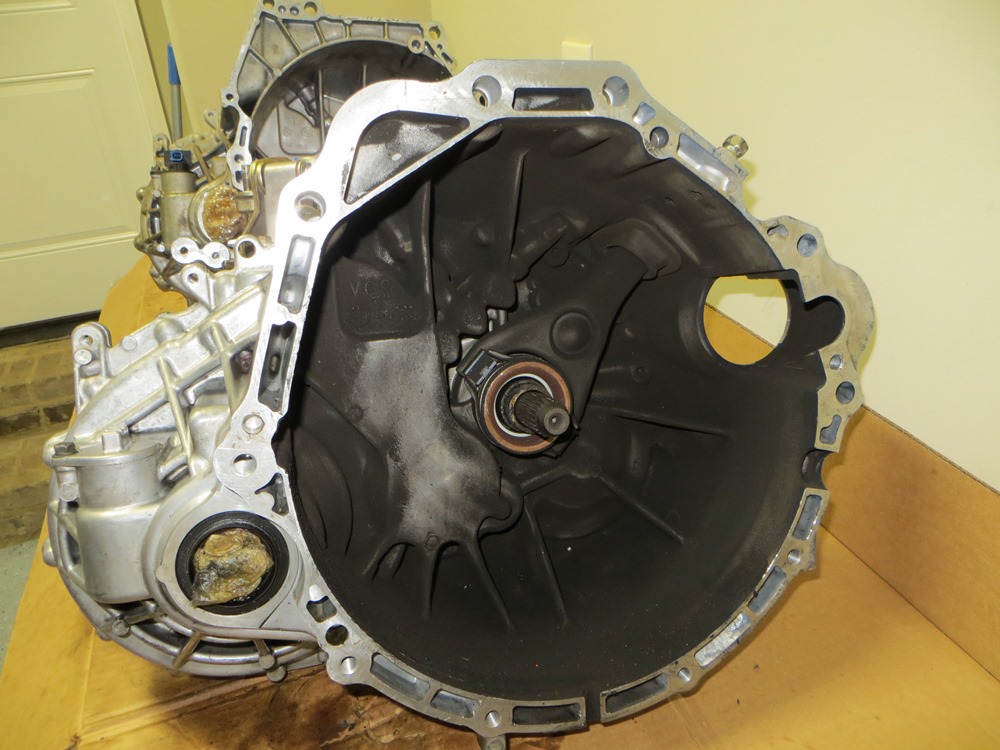

Sentra SpecV Transmission As Received:

Work Setup:

- Set each transmission on cardboard covered work bench side by side (cardboard to protect mating surfaces on transmission and soak up any grease/oil/fluids)

- For fasteners, blow up and print out FSM pages and glue to cardboard. Poke fasteners through on board where you take them out of transmission

- Take off parts from each transmission at same time, label in Ziploc bag

- For large parts, label and place in its own cardboard box

- Clean as you go (scrape off gasket material, use acetone/cloth) to clean

- Follow both factory service manuals for breakdown/buildup

Maxima

SpecV

Maxima Speedo Sensor Block-off Plate

SpecV Speedo Sensor

Maxima Transaxel Case Stamp

SpecV Transaxel Case Stamp

Maxima

SpecV

Maxima Control Assembly, Sensors, and Case Bolts Removed

SpecV Control Assembly, Sensors, and Case Bolts Removed

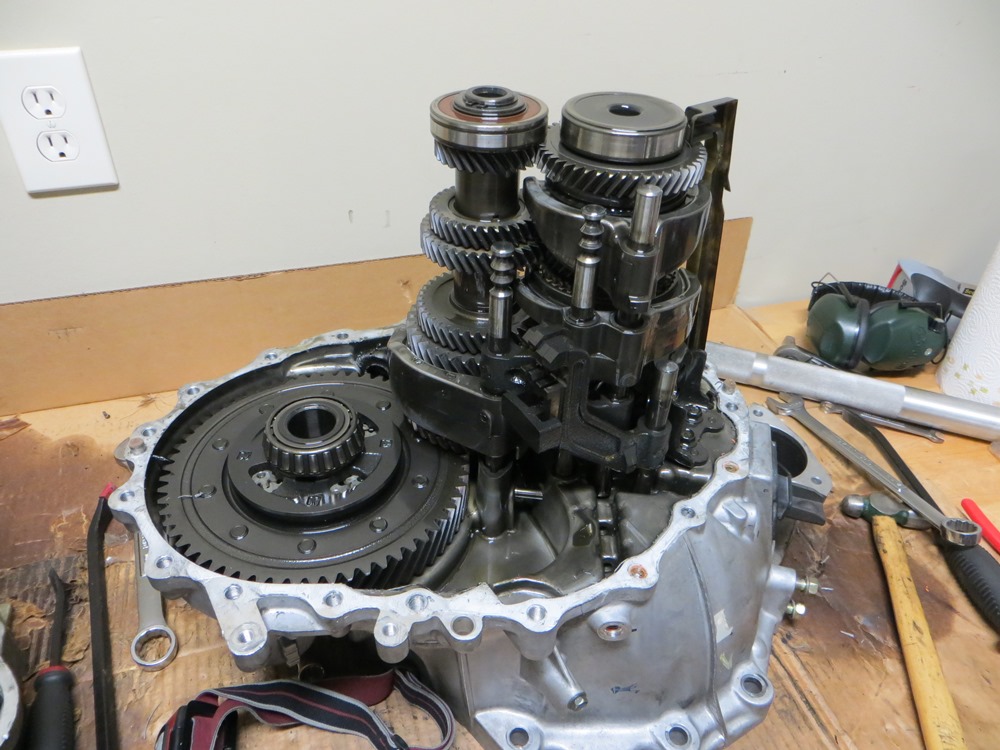

Maxima Transaxel Case Removed (at this point forward, they both look the same

Maxima Spread Spring Debris and Detail

Based on the pictures below, it appears the spread spring in the 3rd-4th synchronizer broke and lodged itself in to prevent the sliding action between gears.

Maxima – Reverse Tilt Mechanism Removed

Maxima – Re-test fitting reverse tilt mechanism (to make sure I understood its reassembly)

Maxima – Reverse shift fork and rod

Maxima – Reverse Gear Stack

Maxima – Re-test fit reverse shift fork

Maxima – Shifter bracket Detail

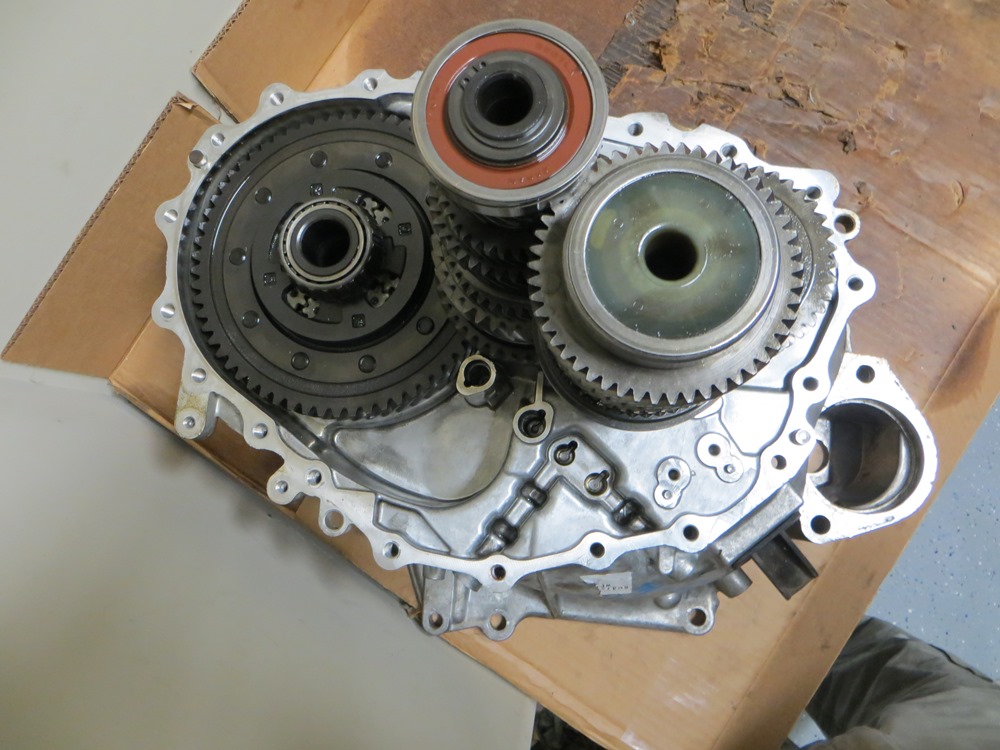

Maxima – Gear Stacks and Differential

SpecV – Gear Stacks and Differential

Maxima – Input, Main, & Reverse Shafts and Axels

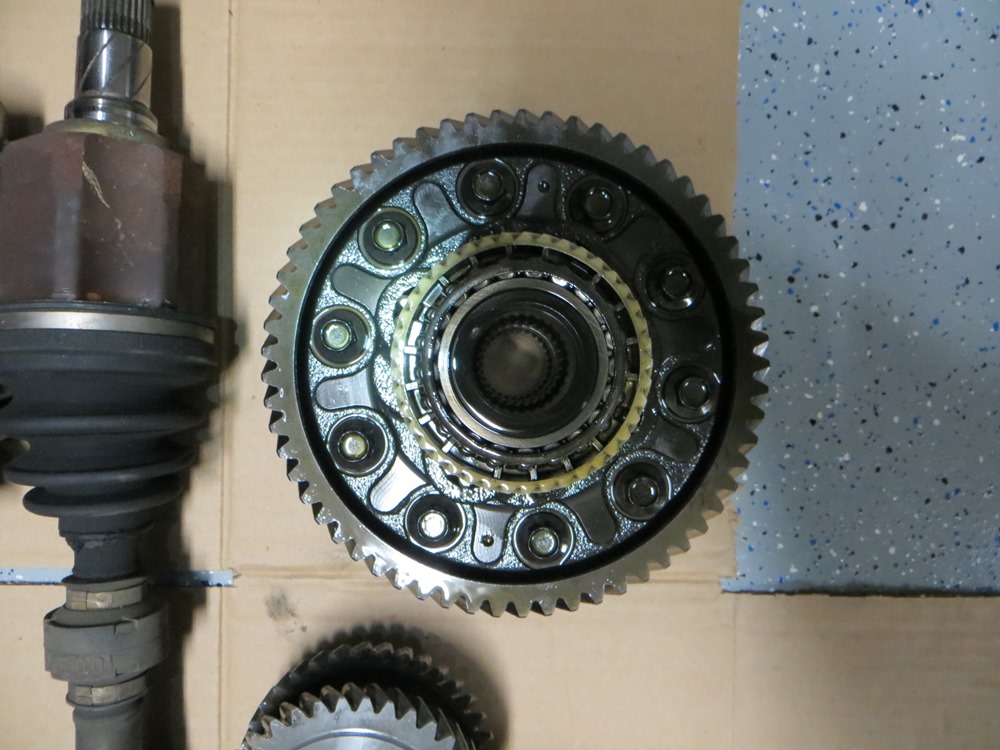

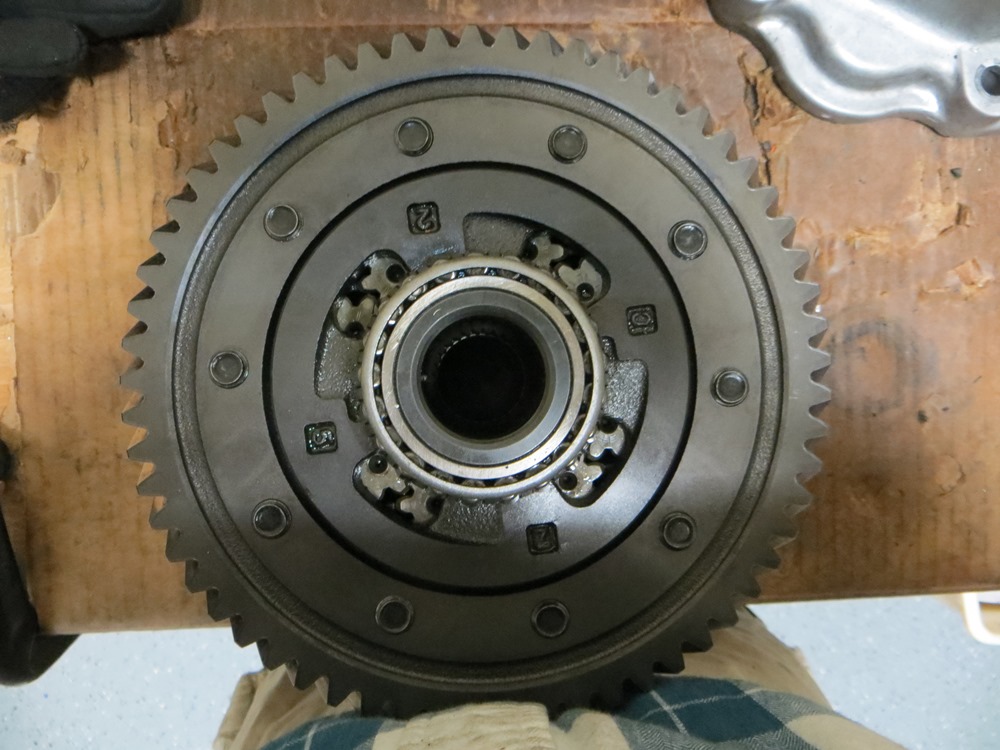

Maxima – Final Drive & HLSD

SpecV – Final Drive and HLSD

SpecV – Reverse Gear Set

Cleaned Maxima Bellhousing (Used acetone and cloth)

Cleaned Differential Side of Bellhousing

Maxima Final Drive and HLSD from SpecV

SpecV Reverse Gear Set

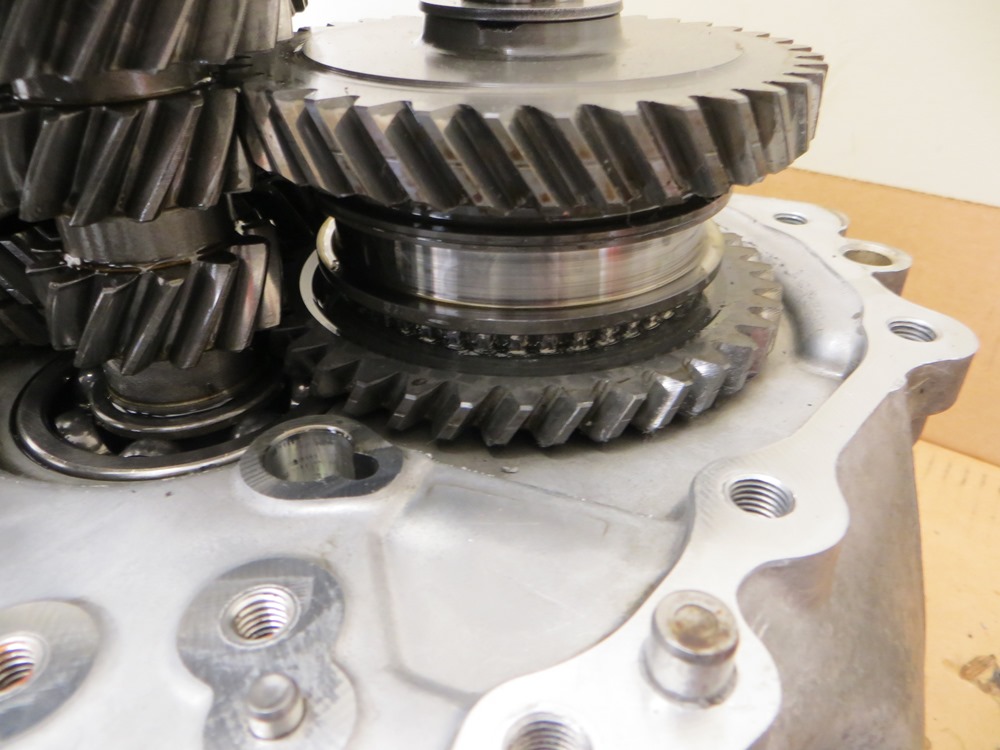

SpecV Gear Stacks and Maxima Final Drive in Bellhousing

Maxima Final Drive Meshed with SpecV Mainshaft

SpecV Mainshaft Meshed with SpecV Input Shaft

SpecV Input Shaft Meshed with SpecV Reverse Gear Set

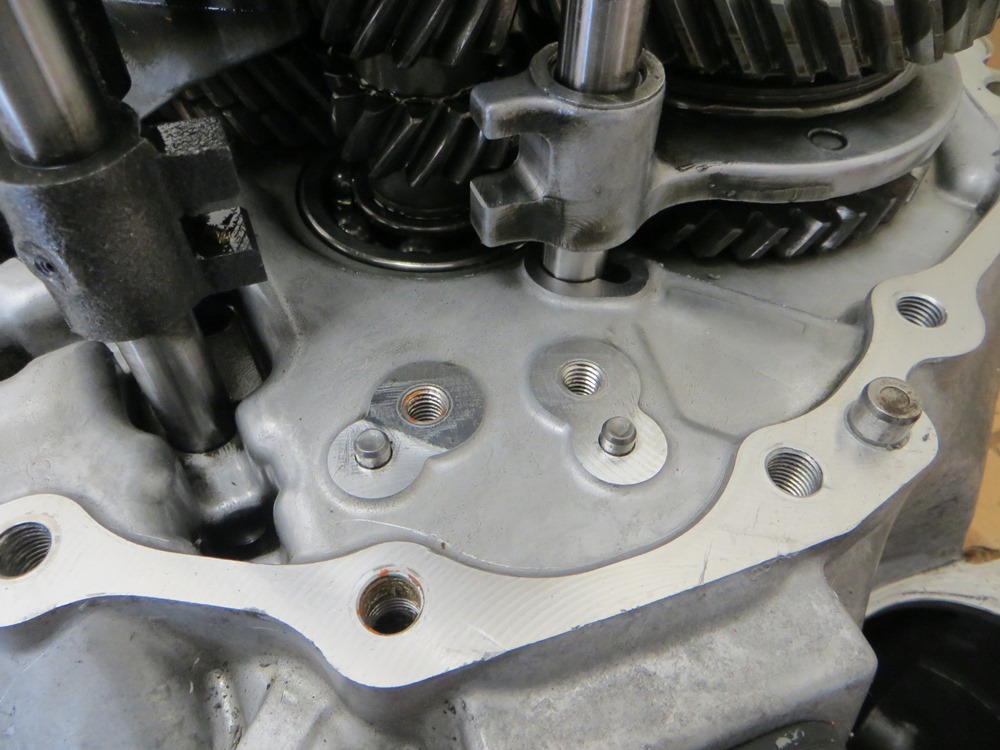

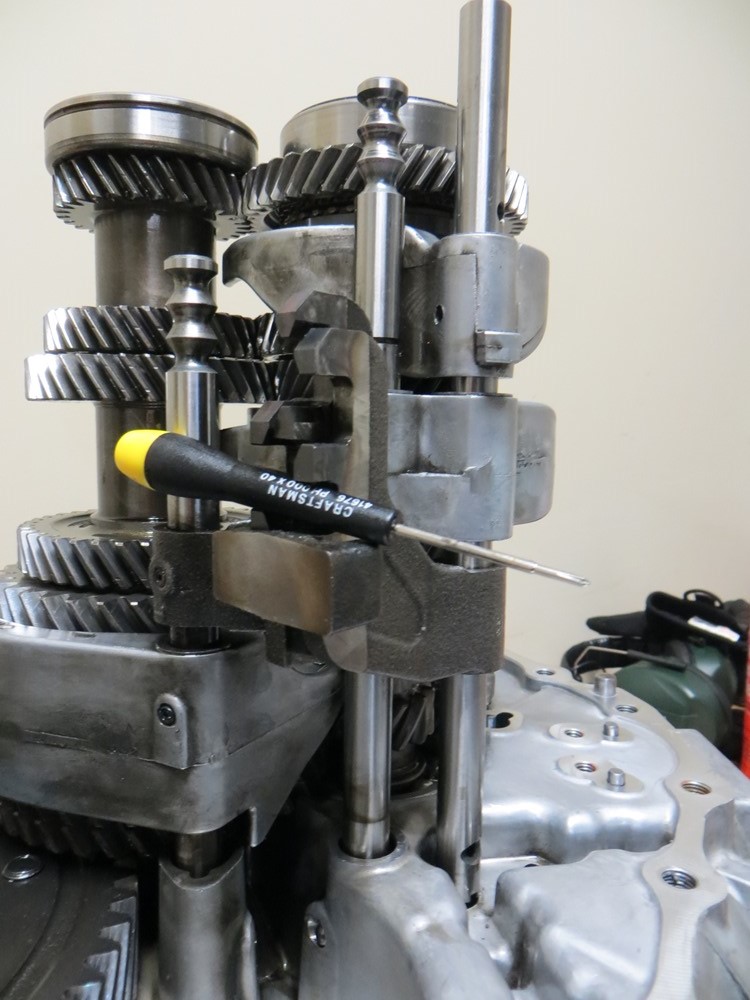

Detail SpecV Main and Input Shaft

SpecV 5th/6th Shifter Fork with Maxima 5th/6th Shifter Fork Rod Detail

The SpecV 5th/6th Shifter Fork Rod had a pretty significant burr on it, and wouldn’t actuate properly. So I used the Maxima version.

SpecV Check Ball and Spacer for 5th/6th Rod

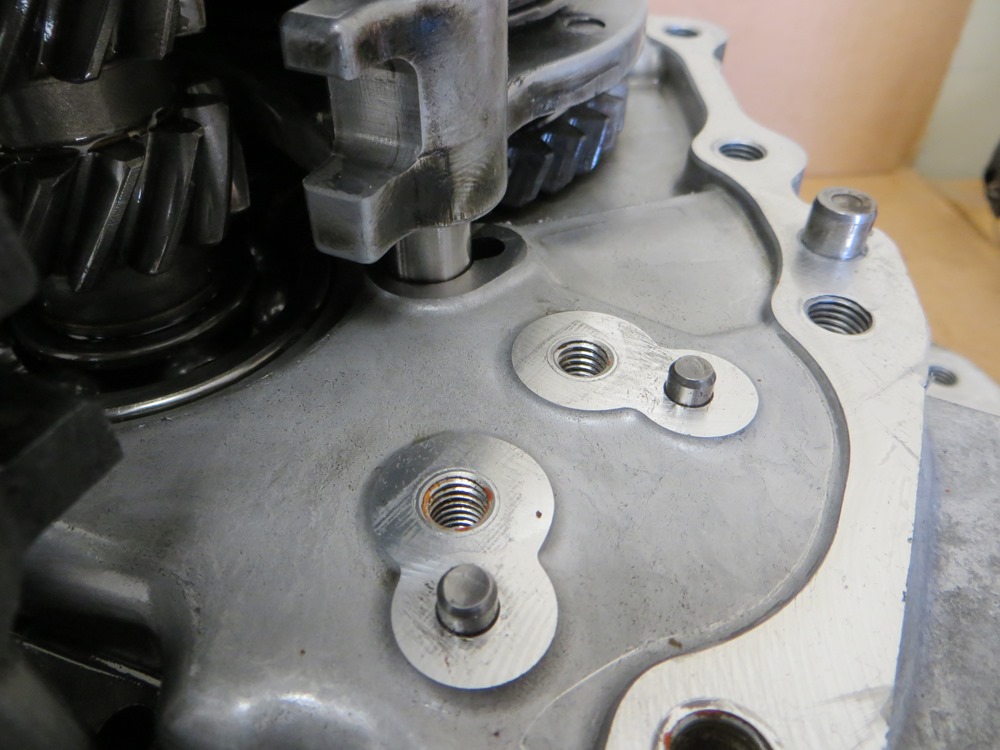

SpecV 1st through 4th Shifter Fork with SpecV Rod Detail

SpecV 1st/2nd Shifter Fork Detail

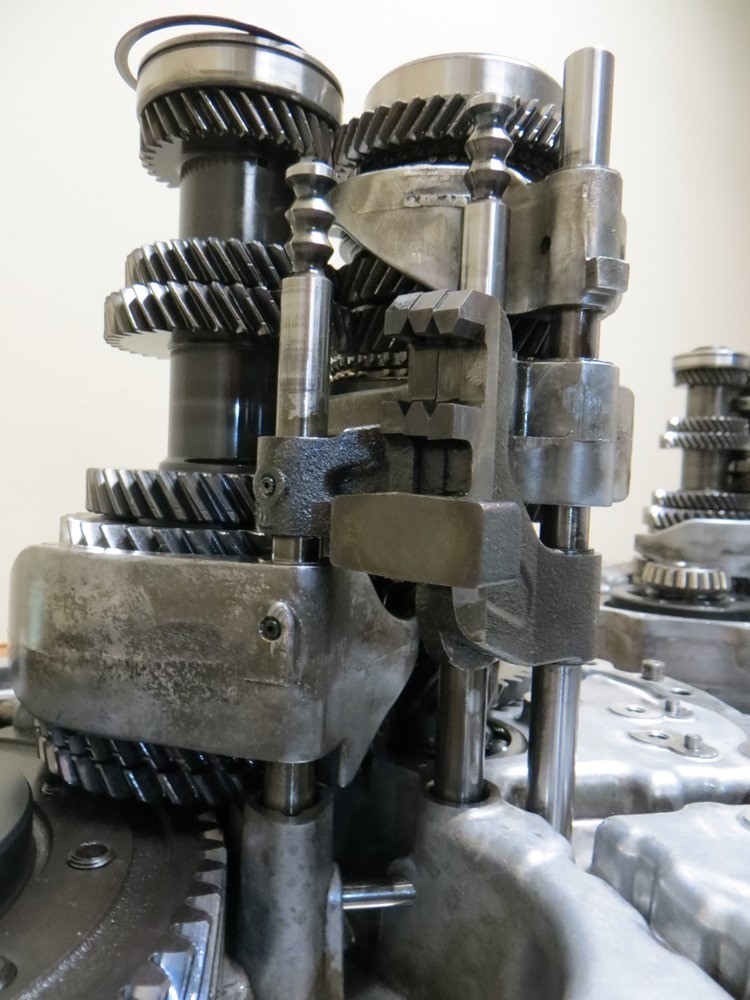

SpecV Reverse Bracket Detail

SpecV Reverse Shifter Fork Detail

SpecV Reverse Tilt Mechanism Assembly

SpecV Check Ball and Spacer for Reverse Rod Mechanism

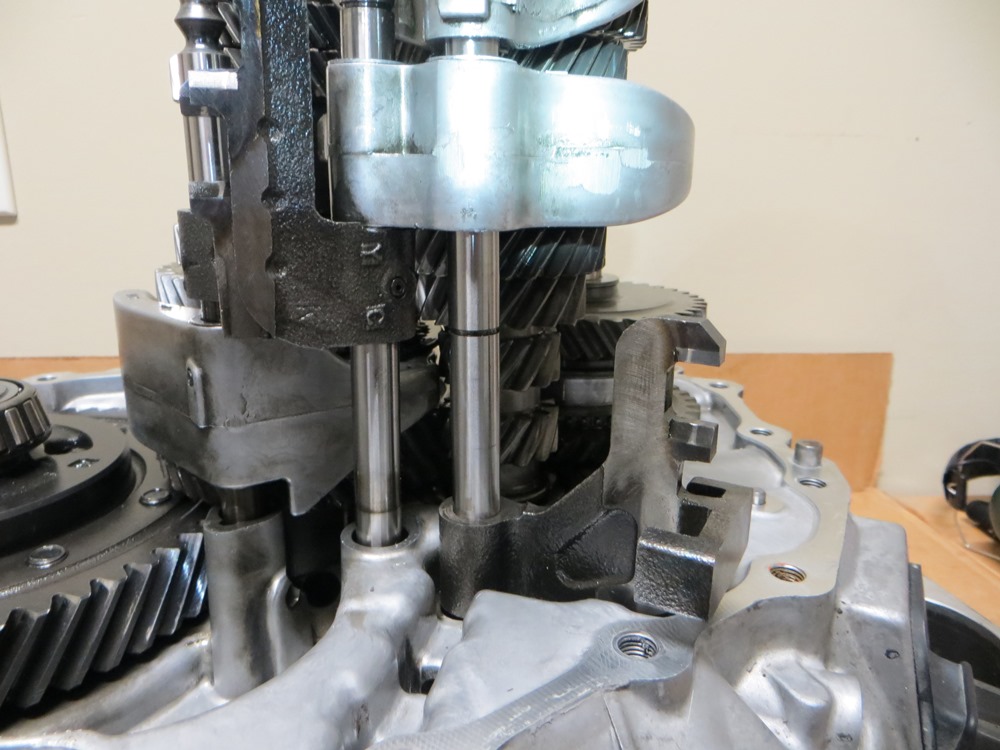

Fully Assembled SpecV Guts and Transaxel Case on Maxima Bellhousing

SpecV Shifting Mechanism

Fully Assembled Transmission on Hoist

![]()

Comments are closed.