Owner: Josh Go Hard Neal

Year: 2012

Model: Maxima

Color: Charcoal

Transmission: 6-Speed Manual

Trim: SV

![]()

Owner: Josh Go Hard Neal

Year: 2012

Model: Maxima

Color: Charcoal

Transmission: 6-Speed Manual

Trim: SV

![]()

Community Member Credit: Eddy

I wanted to add a sequential shift light to my 2002 Nissan Maxima. After doing some research, I decided to go with the Ecliptech Shift-P2 Shift Light Light. Pretty simple and straightforward to install. I ordered it from the link below and these guys shipped it out super-fast. Would recommend ordering from them if you choose to go this route. It was super easy to install as well.

Order Link: https://flyinmiata.com/products/ecliptech-shift-p2-shift-light?variant=43356833251583

Price: $219.00

ECU Pinout:

![]()

Credit: Eddy

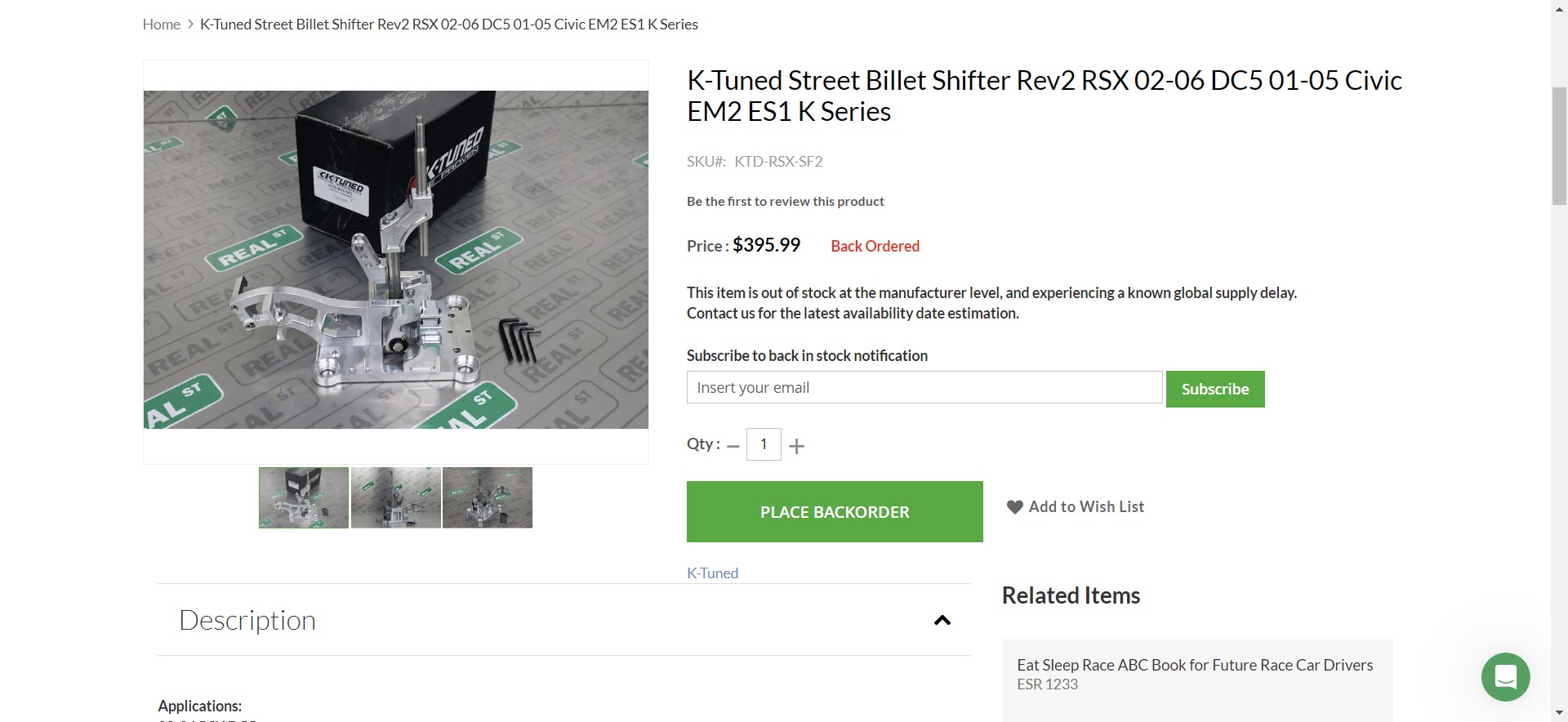

This is a great alternative to replacing your 6-speed knob on your Nissan Maxima. The original knobs are discontinued and no longer available. If you do find them brand new, the pricing is usually over $200. The GTR R34 is the same and will work great. It’s only $30 bucks more than the original pricing of the 2002-2006 6-speed shift knob. You’ll also require an adapter to convert M12 thread to M10, which is available for under $10.00. Additionally, we suggest using Permatex 25210 High Strength Removable Threadlocker.

OEM Part Number: 32865-AA420

Original Price: $160.00 to $180.00

Adapter: https://a.co/d/hvmRViO

Orange Thread Locker: https://a.co/d/2ZfAk2k

Applicable Cars:

![]()

Order Link: https://racespeconline.com/collections/connector-kits/products/gtr-sumi-3-pin

Includes

Fits

![]()

Credit: Sam Jacobs

I promised I would do this, and here it is ages later lol. This is a write up on swapping an auto 5.5 Max to a 6spd. It’s off my memory and old posts, so I will add stuff as I remember. All pictures are on the bottom!

First thing is first, you will need all of the parts to complete the swap before even reading this. There are a few good posts on the Org which cover this. Basics of course are the transmission, shifter assembly and cables, manual trans mount, flywheel and clutch, clutch pedal spacer, clutch pedal itself, and a few other misc things I will add as I think of them. You DO NOT need to swap engine wiring harnesses. If you want to, go ahead, but Nisformance actually recommends not swapping any harnesses or computers.

Onto the process itself- I found myself a donor car, so my first order of business was breaking that car down for all of the parts- this makes things easier.

Step 1. Obviously, you need to cut loose all of the parts from your auto. This includes; The brake pedal, the transmission, the shifter and it’s cable, and cutting off the automatic trans mount. I only cut it on the side of the frame rail, no need to cut the top off, it assists with the strength of the metal.

Step 2. Possibly one of the harder parts of this job for me was mounting the master clutch cylinder. On my car, I had a patch in the firewall insulation on my auto car, but no holes in the firewall itself. What I did was mount the patch piece up to my donor car, and drew a couple holes. I then taped the piece onto my firewall and drilled two holes, followed by the large middle hole for the cylinder itself.

Do not worry about having the best accuracy here, the clutch pedal itself has two bolts under the dash. But please, TAKE YOUR TIME with this. The more precise you are, the better. When installing the clutch pedal and cylinder, be sure to install the spacer in between the firewall and pedal, there are spacers out there, but might not be any new ones left so you may have to get creative. Also install the brake pedal from the manual car while you are down there. Okay, now that your clutch pedal and master cylinder are attached, you can proceed to step 3.

Step 3. Mount your shifter assembly and route the cables through your firewall. What I had to do was cut the bracket that covers the opening a bit, and then I was able to make it work. Use Dynamat to cover the hole, or whatever your creative brain desires. You will have to find two bolts that fit through the trans tunnel as the studs the auto used, no longer exist.

IMPORTANT: Use loctite and lock washers, otherwise you will lose your bolts.

At this point, you should have the pedal/cylinder mounted as well as the shifter, that’s a good bit. You can now install your flywheel and clutch, see other posts for torque specs until I post them.

Step 4. Put the transmission in. This takes a lot of time and patience, esp if you have raised motor mounts. You can look up tips and vids on installing it. As far as mounting the bracket, there’s a couple options here. You can weld it on, or run two bolts through the top like I did. I wanted the part to be removable so pick your poison. This mount doesn’t really hold the motor/trans up, just keeps it all tight and straight when driving hard. Install your MANUAL transmission axles.

Step 5. It’s now time for wiring, this is easy, even for me who hates wiring. So you will see a few methods on wiring the car so that it cranks over. You do as you please, multiple methods work!!! But I suggest to wire it like a factory car. To do this, you will need to have the REAR connector off the clutch pedal. Take one wire and ground it, and the other wire needs to go to the INHIBIT relay in the relay box in front of the battery. You will be tapping into the

Green/Orange wire with the wire off the clutch pedal. This allows the car to function as it came from the factory, it will not crank without the clutch pedal depressed. Now you have to wire the starter. The automatic starter has the connector you need. Cut it off (as well as the one off the manual starter) and attach the auto connector to the manual starter.

You can now connect your shift cables to the trans, one piece clutch line to the slave cylinder (bleed it of course), and you should be ready to start the car.

Step 6. Wire in the reverse lights. On the auto harness, you will see 3 connectors that don’t plug into anything. The bigger of the 3 is what you use. Take the Green/White wire and put it to the green/white wire on the manual trans. Same for the Orange wire (I believe the orange wire you want is the one further from the green/white wire, I will update when I can). I cant remember off the top of my head which orange and which green/white to use. There’s two of each, so just experiment a bit. I can update this when I’m with the car again and have a picture.

At this point you should have a manual transmission car! This is the major steps, of course there are other components such as filling the trans with the PROPER oil, swapping clusters if you don’t want to see the auto gear letters, putting a manual trans shift bezel on, etc…

![]()

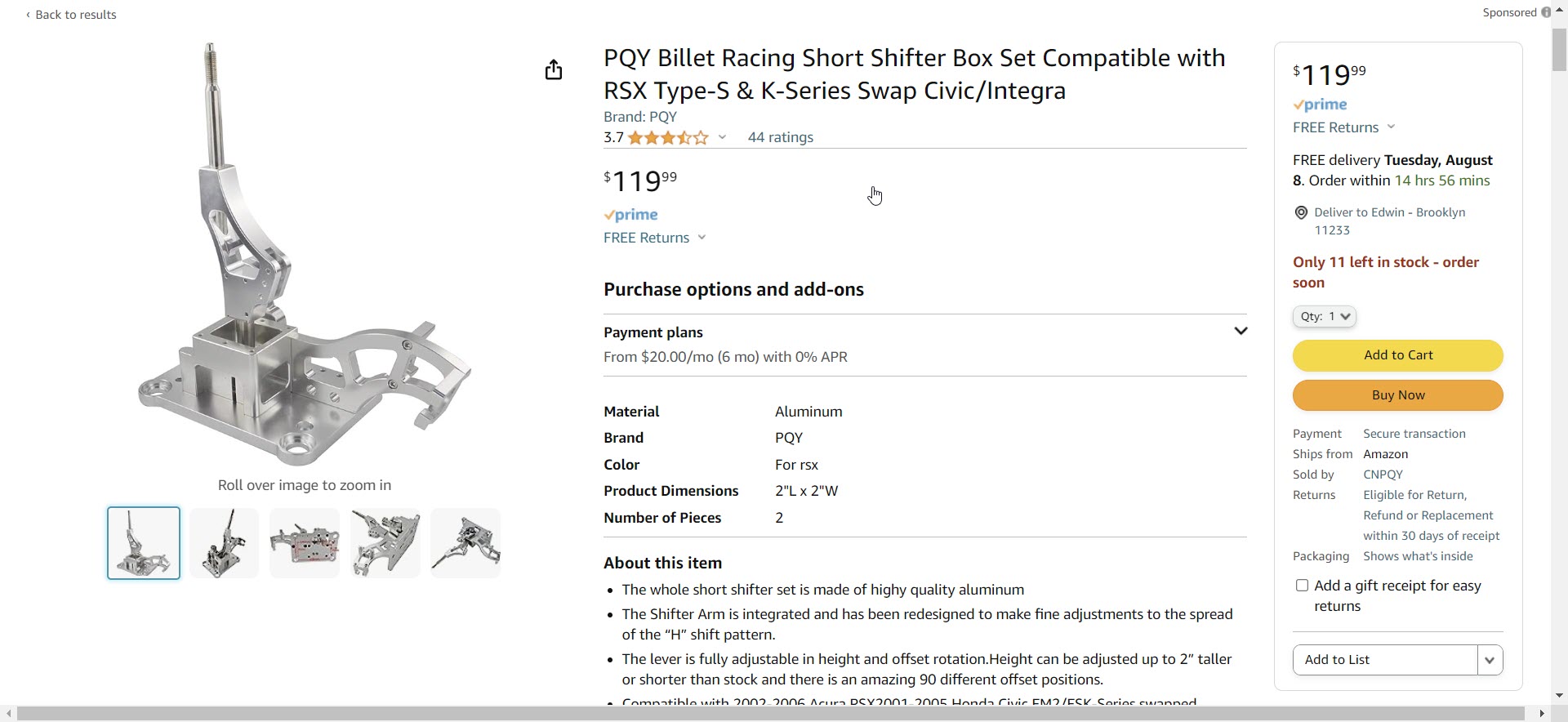

Credit: Joey Edwin

Installation Notes:

![]()

Credit: Jose Vargas

Parts that are needed for the BOV AN setup. These are the parts I used so it can route it the way I wanted, might be a bit different for everyone else depending how you guys have your BOV and location. I bought everything off of this site, I see they don’t carry 3AN anymore but it can still be done with 4AN as well. Post links with 4AN option.

1/8 NPT 3AN Fitting

Tapping this later today when my drill bit and tap arrive from amazon

Original nipple that was on BOV it is a 1/8 NPT

![]()

Credit: xHypex, Mishmosh, and Keven97SE

(Order not strictly important in some cases)

Mishmosh

Directly facing the IAC, this pic of the right side of theIAC shows the 10mm bolt that you need to remove to get the bracket out of the way of one of the 3 retaining bolts. That cable you see is connected to the EGR guide tube.

shows some butterfly’s installed. Pay particular attention to how the end of the rod lines up with the stopping plate (on the right). The butterfly’s are not sided so any side is fine. The rod has one side rounded and the other flat so there is no question which side to mount the valves.

Rear retaining bolt that you need to feel out and remove. 12mm

Side view with the stock intake manifold out. Key structures: Mounting brackets for the two manifold retaining bolts. EGR guide tube. Rear coolant hose. TB/CAI. throttle/cruise cable along firewall with that cylindrical structure attached to the firewall (which I removed cause it made position the new VI a little difficult).

Right rear side pic showing EGR: note the 12mm bolt and the fat washer. In the lower right corner of the pic, you can see the coolant hose. There is also another one on the other side of the EGR (out of view).

Side view of the installed vacuum actuator. Manifold vacuum fed from the Fuel Pressure Reg vacuum line down below >> Vacuum canister >> Switched port of the solenoid >> main port of the solenoid to VI vacuum lever.

Ground bolt–a convenient place to ground. (Credit: xHypex)

Relay that activates MAP switch. Can you tell which it is? (I don’t have ABS)

Vacuum Canister mounted near the strut mount (it will be painted soon)

Nissan vacuum canister adds to the OEM look

Nissan MAP switch

Nissan Check Valve connected to the FPR vacuum via a F fitting

After installing the VI your EVAP will not have a place to mount. On the ’99s the EVAP is a small electrical sensor and sits nicely on top of the manifold. 95-98s have a mechanical EVAP which is larger.

Vacuum actuator arm moves forward when the vacuum kicks in.

Side view

Here’s the FSM diagram of the MEVI

Large, Closeup pictures of the MEVI Collector

MEVI Installed on Ian’s Car

MEVI Installed on Ian’s Car

N/A

MEVI with Cover on my car

Wiring Diagrams

(courtesy of Keven97SE and Mishmosh)

N/A

Alternate Wiring Diagram

FSM Vacuum Diagram

Ian’s Dynoes: Dyno Run 1 and 3 were baseline runs and on 5 the VI opened at 5k.

Dyno HP

Dyno TQ

Dyno HP & TQ

Spreadsheet with RPM, HP, TQ

speedtrip’s dynoes:

CAI/Y-pipe (baseline) CAI

Ypipe with VI Hybrid

Ypipe with VI

Spreadsheet with RPM, HP, TQ

![]()

Credit: Luke Melton

ECUMASTER EMU BLACK is a universal engine control computer that manages the operation of spark-ignition engines, and is designed to work with the most advanced and complex currently available engines. It is the successor to our proven system, the ECUMaster EMU. Common applications for the EMU Black are modified race cars, passenger cars, motorcycles, boats, and stationary engine applications.

Notes:

![]()