Community Member Credit: maximase86

Write-Up: cefirowriteup

Tools:

- Ratchet

- 10mm deep socket

- Extension

- 10mm gear wrench (or normal wrench)

- Dremel

- Heavy-Duty Cutting Discs

- Grinding Bit

- Scissors

- Pliers/Channel Locks

- A friend

- Wire Crimps/Splicers

- Panel Poppers (optional)

Needed Materials

- Galvanized Plumbers Tape

- Automotive Weather Stripping

- Double-sided foam tape

- Zip Ties

- Wiretaps

- Electrical Wire

1. Disconnect the ground to the battery terminal.

2. Remove the cornering lamps. There is a Phillips head screw that holds the lamp to the headlight. Once you removed the screw, just pull the corner lamp out in the direction the car is facing. Note that the cornering lamp may be tough to remove. Note, keep all your existing bolts and screws as you will need to reuse most of them.

3. Remove the bulb from the cornering lamp as well as unhook the harness. Set aside.

4. Remove the grill. There should be clips near the top corners of the grill. Pop these clips and then lift the grill up and out. Set aside.

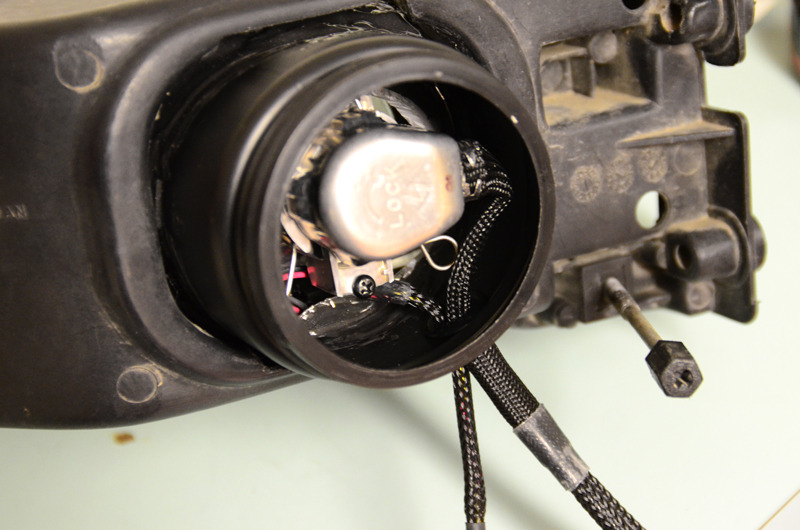

5. Unplug the headlight harness and remove the headlight bulb.

6. Now it’s time to remove the headlights. First, remove the 10mm bolts that hold the headlight to the bracket on the fender. Next, there are 2 10mm nuts holding the inside of the headlights to the car on each side of the radiator. You’ll probably need a deep well 10mm socket, or if you have a set of gear wrenches, this will help out a lot. Once that is removed, pull the headlight in the direction the car is facing. Watch for the adjustment bolts, as they like to snag on things when pulling out. Your car should look like below when you’re finished.

7. Next you will need to remove the little black trim piece that sits under the original headlight. There should be about 3 10mm bolts that hold them in place. Remove them from both sides.

8. Next comes the fun part, time to hack your car up! There are 4 places you want to mark with a sharpie. The main headlight support bracket, the 2 tabs for the corning lamp, and a portion of the frame which you need to make a cut out to allow the lamps to fit. See the following pics:

The upper portion of the support bracket with cut marked.

Cornering Light Tab and Frame with cut marked.

Upper Cornering Tab with cut marked.

Bottom of the headlight support bracket

You have 2 options with this. To help give the ability to revert to stock you can do one of 2 things. You can use panel poppers, or some kind of screwdriver to pop the spot welds at the bottom, or you can bend the bracket down.

9. After you made your marks, go ahead and make the necessary cuts. There are few different tools you could use (i.e. grinder, Dremel, etc). The Dremel might provide the best results. You will need to use the heavy-duty cutting discs, and be ready to use 10-15 discs.

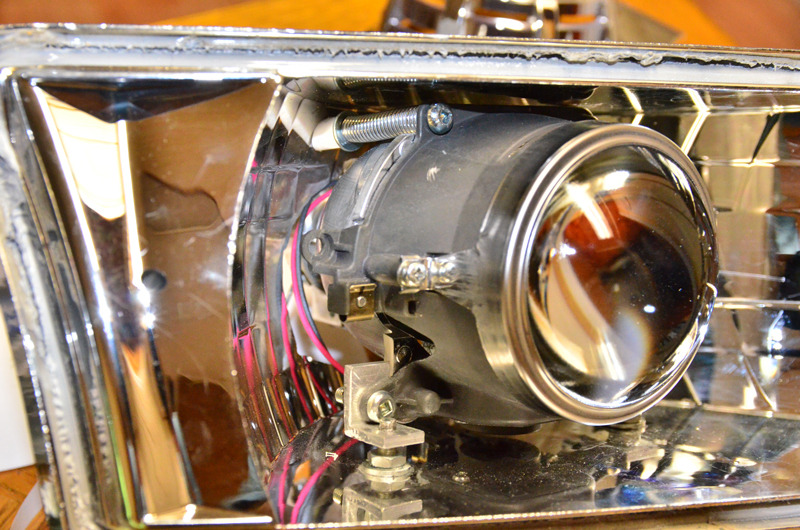

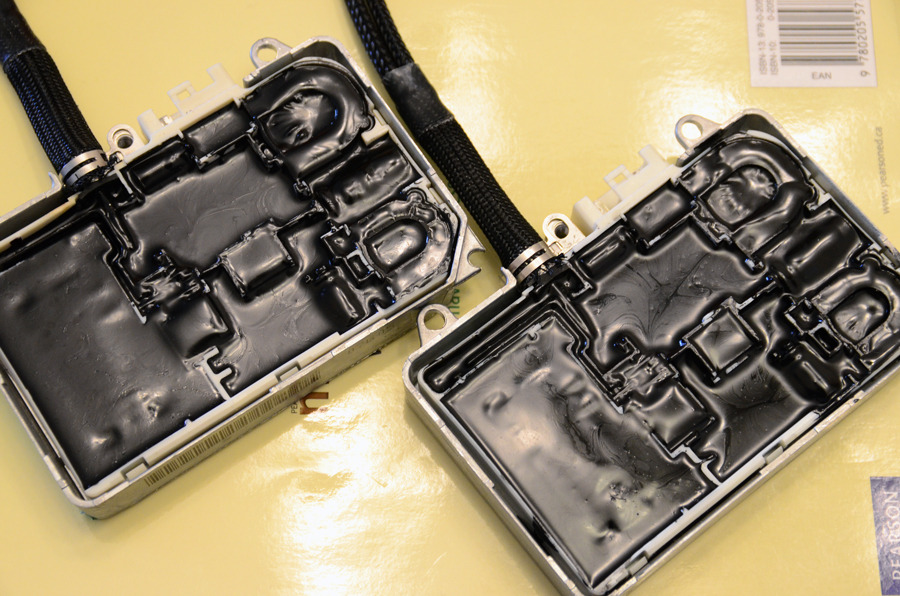

10. Once your finish cutting, and you got the bracket out of the way, it’s time to do a test fitting. Put the Cefiro headlight in place. Make note of any places that might be in the way. Take out the headlight and make cuts as necessary.

11. You may need to make the holes there in the headlight bolts near the radiator larger in order to reduce the gap between the headlight and the fender. It is impossible to get it perfect, but it does help a little.. If this is the case, you can use a Dremel with a grinding bit to enlarge the holes as necessary.

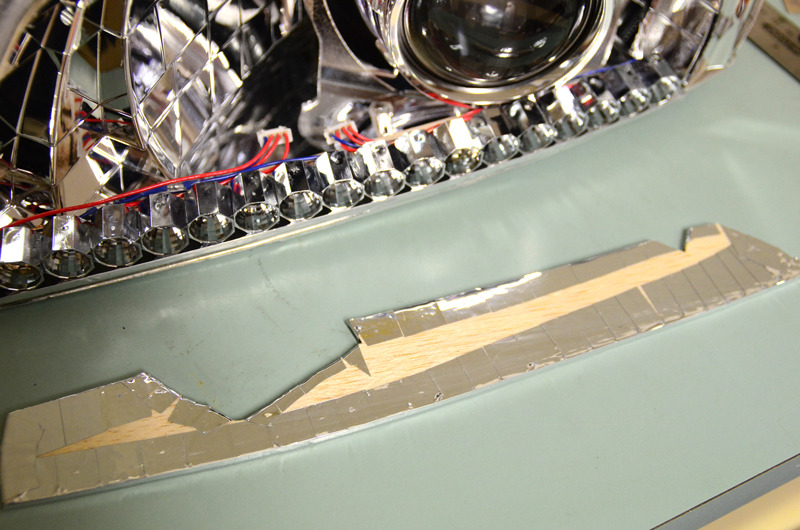

12. Once you have your headlight set the way you want it, you will now need to fill in the gap. (And since you have these instructions because you have a 4th gen, there WILL be gaps).

13. To fill in the gap, you’ll need to get some black weather-stripping. You can usually find a bulk back at your local parts store. What you want to do is with the headlight in place; measure out a piece that will fit the gap best. You may need to do some trimming to get everything to look good. Once you have the piece you need, remove the adhesive backing and attach the weather-stripping to the headlight. Keep in mind; this is sort of a trial and error thing, so you will have to work with it a little before you get everything to work.

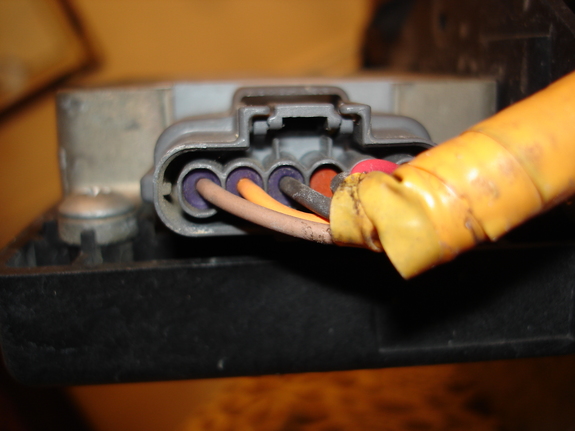

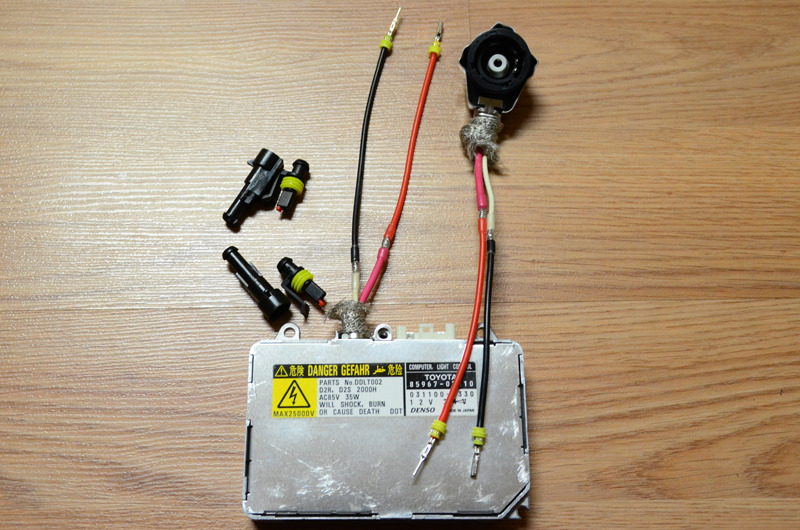

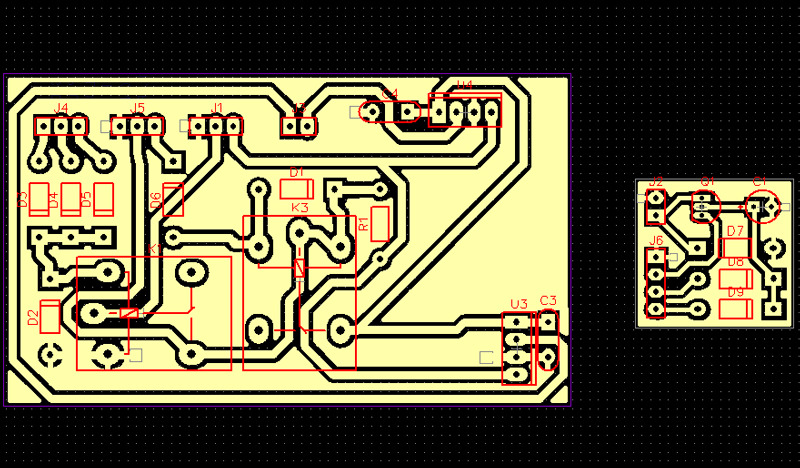

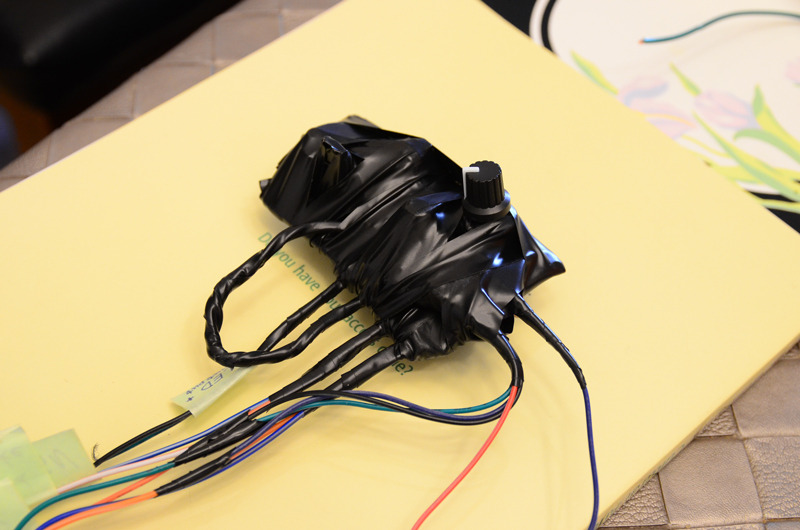

14. Next you want to splice the H4 harness into your existing harness. To do this, it’s easiest to reconnect the ground, and while using a voltmeter, test which wires run which with the lights on. (Black will be ground).

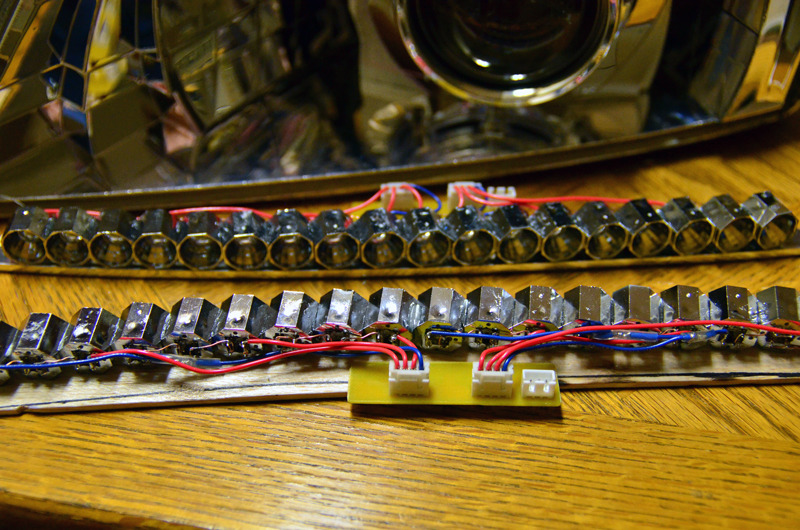

15. Next splice the city lights into the side markers. You may need some extra wire handy to do this

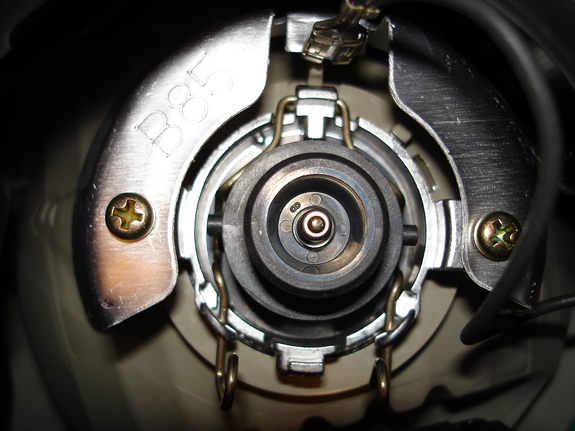

16. Next you will need to convert the parking lamp socket to work on the 1157 Harness. Line up the large tab on the harness with the large notch on the corner housing on the Cefiro. Make note of which notches need to be enlarged to fit the socket in. Take a Dremel with a grinding bit (or Exacto knife) and grind out the notch(s) until you can fit the socket in place. Once this is done, you can install the bulb and socket.

17. Install your H4 bulbs and plug the harnesses in. Then fit the headlight to the car. Bolt down the inner nuts.

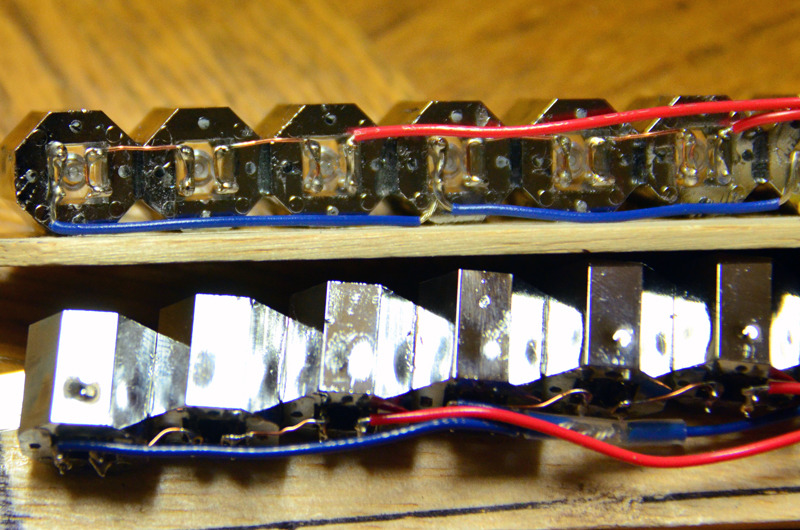

18. Next, removed the forward most bolt on the fender nearest to the headlight. Cut a piece of galvanized plumber’s tape that is long enough to reach from the tab on the Cefiro’s to the hole where the bolt for the fender goes. Be sure to align the holes. You will need to find a bolt and nut that will go through the hole on the tab of the Cefiro lamps to secure the plumbers tape. Once you finish that, bolt the plumbers tape into the fender. You may need to push the headlight inwards for the bolt to go in.

19. Once both headlights are secure, take your grill and clean off the bottom section. Affix some heavy duty double sided tap to the bottom section. Set the grill in place and push down to set the tape. You might need to play with the alignment to get it right. Next you can either use plumber’s tape or zip ties to secure the grill to the radiator support frame.

20. Once everything is back on, close the hood and check fitment. Make adjustments as necessary. Also check to make sure all your lights are working properly.

21. You’ve just finished the Cefiro install. Now that wasn’t so bad was it?

![]()

Final Product: Make sure all mounting points are secured properly, all harnesses connected fully, turn the lights on and enjoy.

Final Product: Make sure all mounting points are secured properly, all harnesses connected fully, turn the lights on and enjoy.