Credit: Gerson Flores

![]()

Community Member Credit: Eddy

The air intake rubber boot cracked on my 2009 7thgen Nissan Maxima. I recently bought a 2020 engine for my 1998 Maxima and it just happens to come with an air intake. I installed it on my 7thgen and it fit worked. Didn’t need to buy a new one or try to hack my existing one.

![]()

Community Member Credit: luke95gxe

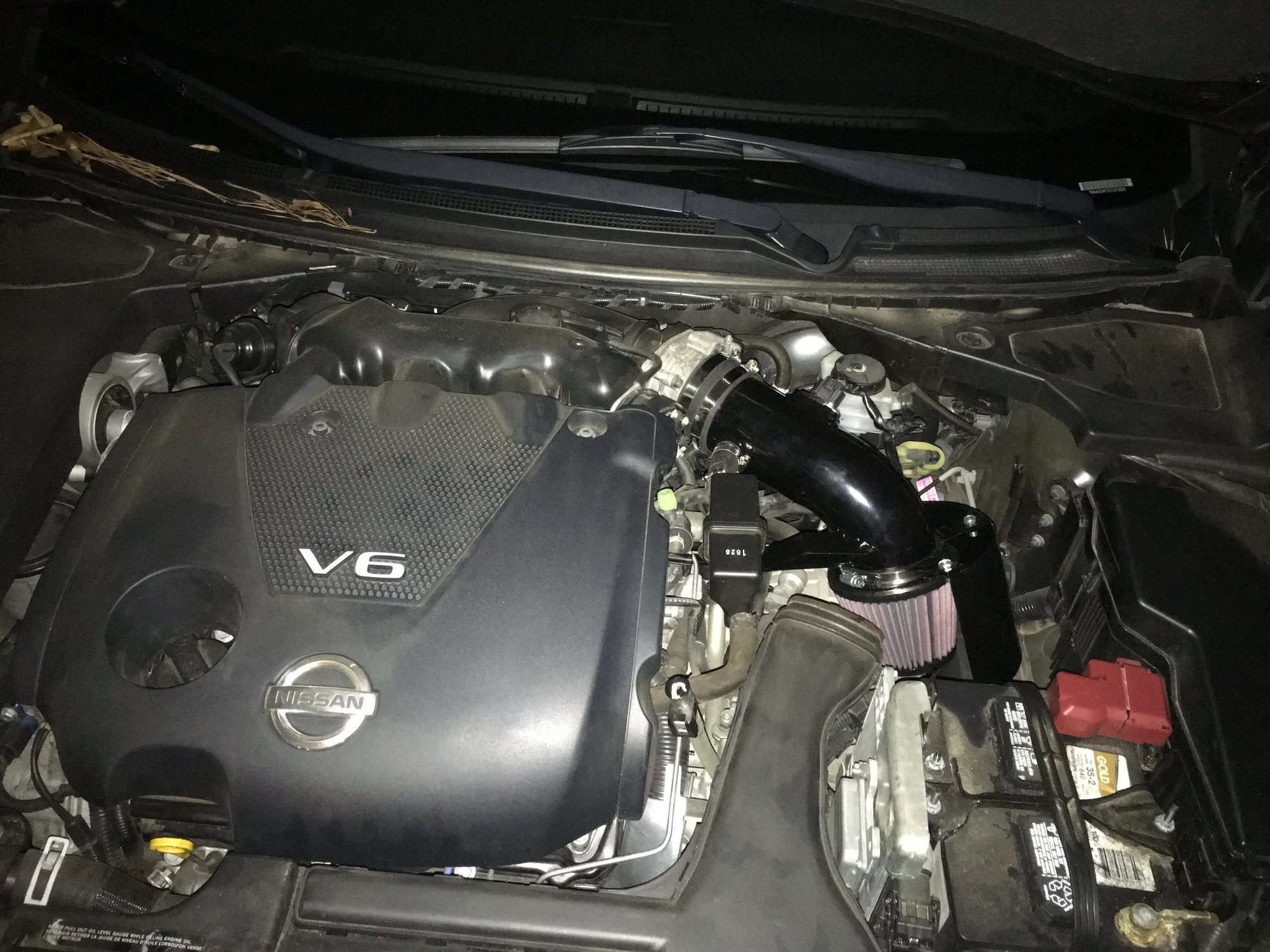

So I decided to install a cold air intake the diff is noticeable and I love it.

Tools Needed

Parts Needed

My ram air intake set up:

Here is the pipe I used. It was beaten up so I painted it.

Remove fuse box and battery on driverside drill pilot holes and cut a hole a lil bigger than 3” in diameter.

Remove drivers-side wheel

Remove the splash guard by Phillips head screws you don’t have to completely remove.

Install cold air piping through the hole

Install air filter

Put splash guard back on and wheel and enjoy a better breathing engine. Finished product

I can definitely feel a difference on pulls than the ram air intake feel free to comment sorry for the crappy pics taken with my cell phone.

![]()

Community Member Credit: ATTappman

Recently I had to remove my UIM to tighten the hose clamps on the coolant hoses connected to the backside of the UIM. Here’s a description of the job with some photos. The car is a 1997 GLE Fed spec.

First, you have to remove the air intake. Start by popping off the four clips that secure the top of the air filter box:

Disconnect the MAF sensor electrical connector:

Disconnect the two large vacuum hoses and one small hose from the resonator:

Note that I unhooked the IACV end of the second large hose, to keep the hose attached to the resonator.

Loosen the hose clamp on the throttle body, wiggle the air duct off of the throttle body, and lift the whole air intake assembly out of the engine bay:

Disconnect the two electrical connectors from the throttle position sensor:

Disconnect the four electrical connectors from the IACV/fast idle solenoids/EGR temp sensor:

Unhook the cruise control and accelerator cables from the throttle lever. Note that the accelerator cable runs underneath the little tab on top of the throttle lever:

Remove the three 10mm bolts that secure the cable brackets to the UIM. Move the whole assembly to the back of the engine bay:

Disconnect the electrical connector on the EVAP purge volume control valve:

Disconnect the electrical connectors to the ignition coils and the front O2 sensor:

Unhook the wiring harness. It’s secured by plastic clips. With a pair of needle-nose pliers, compress the two “wings” on the bottom of the clip while simultaneously lifting up from the top. Move the wiring harness to the passenger side of the engine bay:

Remove the two 10mm and two 12mm bolts/nuts securing the EVAP purge control valve and the EVAP purge volume control valve to the UIM:

Remove the 10mm bolt holding the EGR temperature sensor bracket onto the IACV. This bolt is hard to see – you can locate it by feel. You’ll need a 3″ extension or a deep socket. The EGR temp sensor wire is in the way – make sure to move it aside to keep from pinching it with the socket. (No pics for this – it’s too hard to see).

Remove the three 12mm bolts holding the IACV to the throttle body. You need an extension for the bottom bolt (my camera battery went dead here and I switched to my cell phone camera – the pics are blurry, sorry):

Lift off the IACV, being careful not to lose the gasket in the engine bay:

Move the EVAP valves back toward the driver’s side of the engine bay. Most of the hoses will still be attached:

Remove the clamps on both ends of the PCV hose assembly, remove the 10mm bolts holding it to the UIM, and remove it:

Unscrew the two screws holding each ignition coil, and pull out the ignition coils. (No pics).

Unhook the vacuum hose from the UIM to the brake booster:

Now comes the hard part. The UIM is bolted onto the rear cylinder head with two support brackets. The EGR guide tube is also bolted to the UIM with two bolts. All of these are 12mm. The best way to locate the support bracket bolts is to feel with your hand along the firewall side of the UIM. Here’s what it looks like with a socket and ratchet on one of the bracket bolts:

You can see one of the EGR tube bolts, but you have to locate the other one by feel. It’s difficult to get a socket on the right UIM bracket bolt. You need a pretty shallow socket and a low-profile flex head ratchet (this is one job where Snap-on tools pay off). If you can’t use a ratchet, try a 12mm offset wrench. Once you loosen the bolts, use a socket to spin them off. Be careful not to drop them.

Taking off the left EGR tube bolt:

At this point, I was soaked with sweat and had a backache, so I stopped taking pictures.

The only remaining bolts are the four 12mm bolts on the front of the UIM. There’s a pattern for tightening these bolts, so I loosened them in the opposite order. If you’re looking down at the UIM from the front of the engine bay, the tightening order is 4-1-2-3 from left to right, so take them off in the reverse order.

Now the only thing holding the UIM on is two coolant hoses in the very back. If the UIM won’t separate from the lower intake manifold, take a thin putty knife and gently pry between the UIM and the gasket, being careful not to gouge the UIM.

Next, get an assistant (I used my wife – she’s a good scout) to hold the UIM as far up in the air as they can. This will reveal the two coolant hoses on the back of the UIM. It’s an extreme PITA to loosen the hose clamps and pull off these hoses. When you pull on them, you just pull the UIM and your assistant toward you. It took me a lot of patience and a lot of swearing to get them off. Getting them back on is no fun either. Maybe somebody can share a trick for this.

With the coolant hoses off, you can lift the UIM out of the engine bay. Here’s what it looks like with the UIM removed:

You can see the two support brackets and the top of the EGR guide tube. Here’s what my EGR guide tube looked like the first time I took the UIM off:

Reinstallation, as they say, is simply the reverse of removal.

Be careful not to knock the EGR tube gasket off into the engine bay. If you put in a new EGR tube gasket before reinstalling the UIM, it helps to tie two loops of fine dental floss through the EGR tube bolt holes and the gasket. This will secure the gasket to the EGR tube and keep it from falling off when you’re putting the UIM back on.

When reinstalling the UIM bracket bolts, get your assistant to move the UIM up and down slightly so that you can align the bolt holes on the UIM with the bolt holes on the cylinder head.

As you may have noticed, I rethreaded most of the bolts into their holes to keep from losing them. The ones you can’t do this with are the IACV/EGR temp sensor bracket bolts, the UIM support bracket bolts, EGR tube bolts, and UIM bolts themselves. I made post-its for each set and put the bolts on the post-its.

I used Permatex gasket adhesive to hold the UIM gasket and the IACV gasket in place during reinstallation. It was mildly successful.

That’s about it. Hope this helps somebody.

![]()

Community Member Credit: JakeOfAllTrades

The plastic tube below is the “Sound Generator”. The Sound Generator is the noise you hear that makes your car sound as if it is shifting and it kinda gives a Growling noise when you jump on the CVT.

Nissan made the Sound Generator and piped it into the interior of our cars so that we can hear it and make it seem as though the CVT is going through the gears because without it (Sound Generator) the car/CVT was too quiet and we wouldn’t know what’s going on.

This is the cap I got. it was $2.90 at Lowes.

This is the rubber intake hose I removed to get at the plastic noisemaker tube. It connects the airbox and throttle body.

As you can see, there are three hose clamps that needed to be removed to take the intake hose out. I started by removing the cover from the air filter box. I needed to remove the hose clamp and then also disconnect the mass airflow sensor and the cable ties that held it in place. Here’s what it looked like after I removed the airbox lid exposing my air filter (red filter at bottom of the picture).

After I loosened all three hose clamps. I just pulled up and out on the rubber tube and the plastic “noisemaker” slid out (it was held to the rubber tube with another hose clamp, but I didn’t need to loosen this one until after I got it out). Here’s the rubber intake hose with the plastic noisemaker still attached (It’s resting on the battery in the picture).

I then removed the plastic noisemaker and secured the cap over the hole. I could actually tighten it fairly tight, I kept checking the inside of the hole to make sure it wasn’t collapsing, and it withheld quite a bit of pressure.

After that, I just hooked the rubber intake hose back into place and tightened all the hose clamps back down.

BAM. Quiet cabin.

![]()

Community Member Credit: Maxxi12

Hello everyone!

I recently toyed around with the idea of putting an intake in my Max, so I started reading some threads on here. After looking at the posts and my own engine bay it’s pretty obvious that all intakes are pretty much going to be the same for this car…there’s only one place to go. The filter on the end of it is really the only variable.

So, I went with a bit of a gamble and got a little known (but all over the bay) intake kit from a company called Check Point Tuning, or CPT for short. They have two options for their kits, $99.95 for one that comes with what looks like a ‘Spectre’ type knock-off filter, and $139.95 for the same pipe – but with a K&N filter included. I went with option B. At that price it undercuts K&N’s own air intake system’s price by more than half, and K&N is already on the cheaper end of the spectrum for intakes. So, I’m putting this review out there for people like me, who want to check out their options and maybe came across this low price company on the bay.

Now to get this out there…what every other thread out there for the 7th gen Maxima says is true. No out of the box intake swap will gain power in this car. I’ve built true CAI’s for other cars before and the stock system truly is about the best you can do performance wise. It’s pretty well thought out. So, you won’t be gaining mad VTEC or anything, but if you go into it for the sound, like I did, you won’t be disappointed.

That being said, while I didn’t gain any performance I don’t feel like I lost any either. Driving dynamics are essentially unchanged. So that’s a plus. No low end power loss or any other abnormalities.

Sound wise, well it’s just nifty. Google Maxima K&N intake video and you’ve got the sound, it’s nice. Noticeable even in low RPMs but obviously gets more so as the engine is pushed. Sounds just as great as the 2x expensive name brand with exactly the same level of protection. All around fantastic, unless you’re my gas card.

Now, for the negative –

Yes, it does come with instructions. They are not very good. I suppose that’s because I’m a visual person and I like diagrams, but I’d say if you’ve never really worked on an engine or installed an intake…WITHOUT instructions…this may not be the kit for you. I had to double back a couple of times just because things weren’t completely clear.

Secondly, my third drive after the installation did throw a check engine light. My car had been running and driving as smooth as ever so I knew there was nothing wrong. I cleared the code and it hasn’t come back in days, so I think I’m in the clear. Just a false code more than likely, but still something that others may face.

Lastly, it does come with a heat ‘shield’ but it doesn’t do much. Again though, with these cars there just isn’t any cold air to pull unless you custom build or use the factory intake. Don’t buy a kit and expect performance…it’s all about the sound pretty much, so spend your money on a good filter. The pipe and the shield really won’t matter when compared to other kits.

All in all – great value. That great VQ sound is there, NO performance loss (or gain), and I spent less than half (or even less than that) of the price of the name brand kits with the same K&N protection. What’s not to like?

Please excuse the dirty engine pics. It’s been a long summer.

![]()

Member Credit: Brandan Nankoo,

Mishimoto Photo Credits: Sunday Ortiz and Gerson Flores

No one ever wants to experience the feeling of having to replace a CVT Transmission. Under warranty, it’s not so bad. But out of warranty, it will be a very expensive job. To prolong the life of the CVT, many members have been installing external transmission coolers.

You have various options when it comes to selecting a Transmission Cooler for your 2009-2015 7thgen Maxima. Two of the most popular ones are the Hayden coolers which are universal and applicable to all vehicles and then the Mishimoto coolers.

Please note that you will need an extra quart of Nissan NS-2 or equivalent.

Hayden Automotive Rapid-cool Cooler #677 ($35.00-40.00)

These are very inexpensive and work very well. All rapid coolers include the patented “Flow path design” which increases heat transfer while minimizing pressure drop.

Mishimoto WRX CVT Transmission Cooler 2015+

These are much more expensive and also work well. The best way to purchase these is via a vendor who can get you a great discount.

Tools Needed

1. Jack up the front end

2. Follow Markos video on how to remove the bumper (video below)

3. Blow out Trans cooler to make sure there is no debris inside of it.

1. Drill hole in plastic like in the picture below

2. Route hose through top of the crash bar in between headlight and radiator

3. Pull hose through bottom hole beside the wire that leads to crash sensor

4. Apply a bit of CVT fluid to the inlets of the cooler (this helps the hose slide on better

4. Apply a bit of CVT fluid to the inlets of the cooler (this helps the hose slide on better

5. Put the clamps on the hose and attach to the cooler (tighten clamps)

6. Place the foam pads on the back of the 4 corners of the cooler (supplied with cooler)

6. Place the foam pads on the back of the 4 corners of the cooler (supplied with cooler)

7. Attach the bottom of the cooler with the supplied zip ties

8. Zip tie each hose with the long zip ties. Top one is tied together with the cylinder beside the ac condenser and the bottom to the wire beside it (reference pics above)

9. Cut hose in half using knife

10. Place pan under car

11. Disconnect factory cooler line from radiator which is located on the bottom just above radiator hose (factory clip needs to be squeezed with a pair of pliers)

12. Connect the line from the top of the top of the cooler to the bottom of the radiator with the new clamp

13. Disconnect the other end of the factory line (has the same style clip as the other factory one)

14. Route the other hose coming from the cooler to the end of the factory line and tighten the clamp (make sure there is no kinks in the line)

14. Route the other hose coming from the cooler to the end of the factory line and tighten the clamp (make sure there is no kinks in the line)

15. Double check all connections

16. Lower the car but don’t put the bumper on yet

17. Measure how much fluid came out when disconnecting the line

18. Remove CVT dipstick and add the same amount of new fluid that you measured of the old plus add approximately 150ml extra to accommodate the cooler

19. Start the car and warm up to operating temperature

20. With foot firmly on brake run through all the gears

21. Turn the car off and double check the level is in the proper range and add if needed

22. Check for leaks

23. Put bumper back on

24. Recheck all connections after 100 miles

25. Enjoy your new trans-cooler!

Additional Photos (Installation and Position of Mishimoto Cooler):

![]()